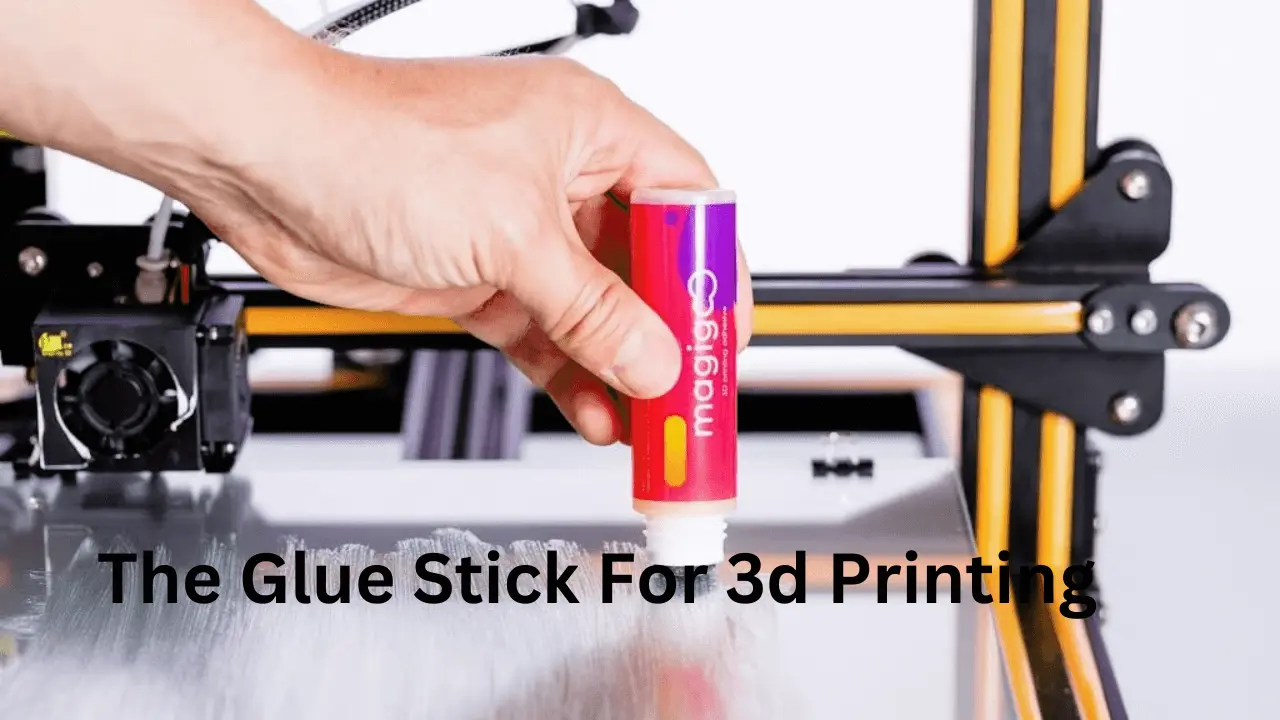

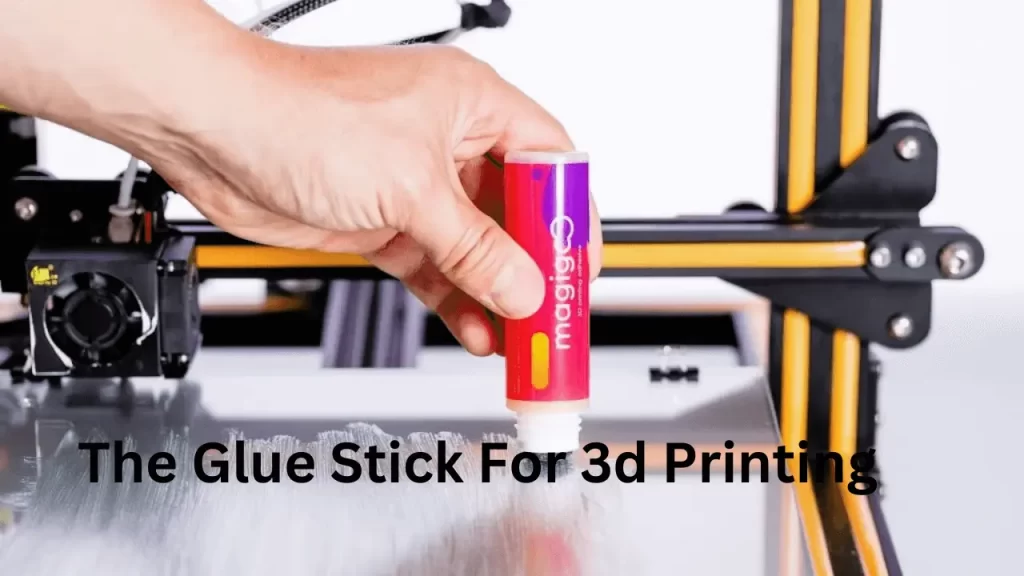

Are you looking for the Glue Stick For 3d Printing? 3D printing has revolutionized the manufacturing industry, making it possible for businesses and individuals to create complex objects with ease. However, a key part of the 3D printing process is ensuring that the printed object adheres properly to the print bed. This is where glue sticks come in – they provide an easy and effective way to ensure that your prints stay firmly in place during the printing process.

Let’s dive into this peculiar topic and uncover the taste, health risks, and even unique uses of glue beyond its intended purpose.

Choosing the right glue stick for 3D printing can be a daunting task, especially with the multitude of options available on the market today. Factors such as adhesive strength, ease of application, and compatibility with different materials all play a role in determining which glue stick will work best for your specific needs.

In this article, we will explore some of the most popular types of glue sticks used for 3D printing and provide guidance on how to choose the right one for your projects.

Glue Stick For 3d Printing- Takeaway

- Glue sticks are an effective solution for ensuring proper adhesion to the print bed when 3D printing.

- When choosing a glue stick, it’s important to consider factors such as adhesive strength, ease of use, and compatibility with the materials being printed.

- There are different types of glue sticks available for 3D printing, including PVA, ABS, PETG, PLA, and Nylon, each with its own pros and cons.

- Factors such as filament type, print bed texture and temperature, and humidity levels can all affect glue stick performance, so it’s important to follow best practices for applying glue sticks to ensure the best results.

Types of Glue Sticks

This discussion focuses on the different types of glue sticks used in 3D printing, including PVA, ABS, PETG, PLA, and Nylon.

Each type of glue stick has its own specific properties that make it suitable for a particular 3D printing material.

Understanding the differences between these types of glue sticks can help ensure successful adhesion and improve the overall quality of your 3D prints.

PVA Glue Sticks

PVA glue sticks have been found to be effective in improving the adhesion of 3D prints to the build plate, thereby reducing warping and enhancing print quality. While there are alternative options available for adhesive purposes such as ABS juice or hairspray, PVA glue sticks have proved successful due to their ease of use, low toxicity levels, and affordability.

When applied correctly, the PVA glue stick creates a thin layer between the print and the build plate that helps the print to stick better without leaving any residue on either surface. The effectiveness of PVA glue sticks can vary depending on factors such as humidity, temperature, or printer settings but they remain a popular choice among 3D printing enthusiasts.

Furthermore, they are also safe for use at home since they do not emit harmful fumes like some other alternatives. Moving onto the next section about ‘abs glue sticks’, it is important to understand that each type of adhesive has its own unique properties and should be used according to specific requirements.

ABS Glue Sticks

ABS glue sticks are a popular adhesive option for 3D printing enthusiasts due to their ability to bond ABS plastic parts together with high strength and durability.

The benefits of using ABS glue include its resistance to heat, chemicals, and impact, making it ideal for applications that require long-lasting bonding solutions.

When applying an ABS glue stick, it is important to ensure that the surface is clean and dry before use. Additionally, it is recommended to apply the glue in thin layers and allow sufficient drying time between each layer. This will prevent any air pockets from forming and ensure a strong bond.

Overall, ABS glue sticks provide a reliable adhesive solution for those working with ABS plastic in 3D printing projects.

Moving onto the subsequent section about ‘petg glue sticks’, these too offer unique advantages as an adhesive option for 3D printing enthusiasts.

PETG Glue Sticks

PETG glue sticks are a highly sought-after adhesive option for 3D printing enthusiasts due to their unique properties and ability to bond PETG plastic parts together with exceptional strength and durability.

Compared to other types of adhesives, PETG glue sticks offer numerous benefits such as being easy to use, creating a strong bond, and not leaving any residue or mess behind. Additionally, PETG glue sticks provide excellent heat resistance which is important when working with high-temperature materials. When compared to ABS glue sticks, PETG glue sticks have the advantage of being less prone to cracking and warping during the printing process.

However, it is important to note that while PETG glue sticks may be the preferred choice for bonding PETG parts together, they may not work as well with other types of plastics or materials. In the next section, we will explore PLA glue sticks as another potential adhesive option for 3D printing applications.

PLA Glue Sticks

One alternative adhesive option for 3D printing is the use of PLA glue sticks, which offer a unique set of properties and advantages when compared to other types of adhesives. If you are considering using PLA glue sticks in your 3D printing projects, here are some benefits you can enjoy:

(1) They provide excellent adhesion for PLA filaments without leaving any residue or damaging the print bed surface;

(2) They are non-toxic and safe to handle, making them an ideal choice for those who prioritize safety;

(3) They are easy to apply and do not require any specialized tools or equipment; and

(4) They can also be used as filler material for small gaps or imperfections on printed parts.

To ensure optimal results with PLA glue sticks, it is important to follow some application tips such as cleaning the print bed surface thoroughly before applying the adhesive, using a thin layer of glue evenly spread over the surface, avoiding excessive use that may cause warping or distortion, and allowing sufficient time for the glue to dry before starting the printing process.

While PLA glue sticks have their advantages, they may not be suitable for all types of filaments and materials. For instance, nylon filaments require a different type of adhesive due to their unique properties.

Nylon Glue Sticks

The Nylon filaments require a specific type of adhesive that can effectively bond the material to the print bed surface. Nylon glue sticks are designed to provide a strong bond between the nylon filament and the print bed, ensuring that prints adhere securely during printing. These glue sticks contain special ingredients that improve nylon bed adhesion by creating a strong bond with the print bed surface.

When choosing a glue stick for 3D printing with nylon filament, there are several factors to consider such as compatibility with your printer’s build platform and nozzle size, ease of use, and overall effectiveness in achieving reliable adhesion for successful prints.

Factors to Consider When Choosing a Glue Stick

When considering which glue stick to use for 3D printing, it is important to take into account various factors that can impact the success of your project.

Factors affecting glue stick performance include the type of filament being use. The surface texture and temperature of the print bed, and the humidity levels in the environment.

It is also essential to apply glue sticks correctly by ensuring even coverage on the print bed and avoiding excess buildup.

Tips for applying glue sticks correctly include using a thin layer of glue, allowing sufficient drying time before printing, and avoiding contact with bare skin.

Paying attention to these factors can help ensure that your 3D prints adhere properly without warping or shifting during printing.

Comparison of Different Glue Sticks

This subtopic will compare the various glue sticks available for 3D printing and their respective pros and cons.

PVA glue sticks are know for their ease of use, but they can be messy and have a slower drying time.

ABS glue sticks provide a strong bond but require more effort to apply and can emit fumes during printing.

PETG glue sticks offer good bonding strength with fewer fumes, while PLA glue sticks are easy to apply but may not work well with certain filaments.

Nylon glue sticks are durable but require thorough cleaning before use.

Pros and Cons of PVA Glue Sticks

One option for securing 3D prints to the build plate is using PVA glue sticks, which have their own set of advantages and disadvantages. When compare to other adhesives such as hairspray or ABS glue sticks, PVA glue sticks are consider safer due to their non-toxic nature.

However, they may not be ideal for prints that require high precision as they can create a slight texture on the bottom of the print. Additionally, PVA glue sticks require more time and effort to apply since they need to be layer multiple times before printing. To further emphasize this point, the following table compares the benefits and drawbacks of using PVA glue sticks in 3D printing:

| Pros | Cons |

|---|---|

| Non-toxic | Creates texture on print surface |

| Easy cleanup | Requires multiple layers for best results |

| Affordable | Longer application time |

Pros and Cons of ABS Glue Sticks

ABS glue sticks offer a unique set of advantages and disadvantages that should be carefully considered before use in 3D printing. ABS glue sticks are formulating specifically for bonding ABS materials, which is ideal for users who frequently work with this material. They provide excellent adhesion, creating a strong bond between the printed object and the build plate, resulting in minimal warping or detachment during printing.

However, they may not be the best option for all users as they can release toxic fumes when heated, requiring proper ventilation to reduce health risks. Additionally, alternative adhesives such as tape or hairspray may be more suitable for some applications depending on the specific needs of the user. Furthermore, application techniques can also impact the effectiveness of ABS glue sticks, so it is important to follow instructions carefully to achieve optimal results.

Understanding both the advantages and disadvantages of using ABS glue sticks is crucial in making an informed decision about which adhesive to use in your 3D printing projects. The subsequent section will explore the pros and cons of PETG glue sticks as another potential adhesive option without repeating any information already stated previously.

Pros and Cons of PETG Glue Sticks

PETG is a popular filament option for 3D printing, and understanding the advantages and disadvantages of PETG glue sticks can help users achieve optimal adhesion.

Compared to other adhesive options, PETG glue sticks offer several benefits, including excellent bonding strength, easy application and removal, and compatibility with a wide range of materials. However, there are also some drawbacks that users should consider before using this type of glue stick.

One disadvantage is that it may not be as effective on certain surfaces or in extreme temperatures. Additionally, PETG glue sticks tend to have a shorter shelf life than other adhesives due to their moisture sensitivity.

Overall, PETG glue sticks can be a reliable option for achieving strong bonds in 3D printing projects. Users should weigh the pros and cons carefully before making a decision on which adhesive to use.

Moving forward into the subsequent section about ‘pros and cons of pla glue sticks,. It is important to consider how PLA compares with other filament options when choosing an appropriate adhesive solution.

Pros and Cons of PLA Glue Sticks

When considering adhesive options for 3D printing projects. It is important to weigh the advantages and disadvantages of PLA glue sticks.

One advantage of using PLA glue sticks is that they are environmentally friendly. Since they are made from natural materials like cornstarch. Additionally, PLA glue sticks have a low melting point. Which means that they can be use with 3D printers that operate at lower temperatures.

However, one disadvantage is that they may not work on all types of surfaces as they tend to be less sticky than other adhesives. Best practices for applying PLA glue sticks include ensuring that the surface is clean and dry before application. Only applying a thin layer to avoid warping or unevenness in the final product.

With these considerations in mind. It’s important to explore alternative adhesive options such as nylon glue sticks to determine best for your specific project needs.

Pros and Cons of Nylon Glue Sticks

The use of nylon glue sticks in 3D printing projects has both advantages and disadvantages that should be carefully consider.

One advantage is that nylon glue sticks have a higher melting point than other types of glue sticks, making them suitable for use with high-temperature filaments like ABS or PETG. Additionally, the adhesive strength of nylon glue sticks is generally stronger than that of PLA or PVA glue sticks.

However, one disadvantage is that the strong adhesive properties can make it difficult to remove printed objects from the print bed without damaging either the object or the bed surface. Furthermore, some users have reported issues with stringing or oozing when using nylon glue sticks.

Overall, when deciding whether to use nylon as a glue stick for 3D printing, it’s important to weigh these pros and cons against those of other types of glue sticks and consider which type will work best for your specific project needs.

Conclusion

When it comes to 3D printing, choosing the right glue stick is crucial for ensuring that your prints adhere well to the build plate. There are several types of glue sticks available in the market, including PVA (polyvinyl acetate), ABS (acrylonitrile butadiene styrene), and PETG (glycol-modified PET). Each type of glue stick has its own unique properties and advantages.

In conclusion, selecting the right type of glue stick is critical for achieving successful 3D prints. By taking into account factors such as print material and environmental conditions. you can make an informed decision about which type of glue stick will work best for your specific needs. Experimenting with different types of adhesive can help you find the one that works best for you and your printer setup.