Epoxy glue is a versatile adhesive that has become increasingly popular in various industries, including construction, woodworking, and automotive repair. This type of glue is known for its exceptional strength, durability, and resistance to water and chemicals. It is commonly used to bond different materials, such as metal, wood, plastic, and glass.

However, using epoxy glue requires proper knowledge and skills to achieve the desired results. This comprehensive guide aims to provide a step-by-step process on how to use epoxy glue for various projects. It covers the different types of epoxy glue, safety precautions, surface preparation, mixing and application, tips and tricks, and additional resources.

By following the instructions and recommendations in this guide, you can ensure that your epoxy glue project is successful and long-lasting.

Introduction to Epoxy Glue

The initial segment of this discourse explores the fundamental properties and characteristics of the bonding agent widely recognized as a versatile and robust adhesive substance widely employed in numerous industries and applications.

Epoxy glue is a two-part adhesive system that consists of resin and hardener, which must be mixed together in equal proportions to activate the reaction process that forms a strong and durable bond.

The uses of epoxy glue are extensive, ranging from automotive repairs, construction projects, electronics manufacturing, and even art and craft applications.

Among the advantages of using epoxy glue include its high strength, resistance to water and chemicals, and ability to bond different types of materials.

It is also versatile in terms of its curing time, viscosity, and color options.

Understanding the different types of epoxy glue available in the market is crucial in selecting the appropriate adhesive for a specific project.

Types of Epoxy Glue

Familiarizing oneself with the different types of epoxy available in the market can greatly enhance one’s ability to select the appropriate adhesive for a given application, leading to greater efficiency and overall satisfaction with the end product.

There are numerous epoxy glue brands available, each with specific properties and uses. Some of the most common types of epoxy glue include: (1) clear epoxy, which is ideal for projects that require a transparent finish, (2) fast-setting epoxy, which dries quickly and is ideal for time-sensitive projects, (3) high-temperature epoxy, which is designed to withstand extreme heat and is ideal for automotive and industrial applications, and (4) marine-grade epoxy, which is waterproof and resistant to saltwater and other corrosive elements, making it ideal for boat repairs and other marine applications.

When choosing the right epoxy for the job, it is important to consider the materials being bonded, the conditions the adhesive will be exposed to, and the required curing time. With the right knowledge and selection, one can achieve optimal results. However, it is also important to take necessary safety precautions when working with epoxy glue.

Safety Precautions

This section emphasizes the importance of taking necessary safety precautions when working with epoxy adhesive, similar to donning protective gear before entering a hazardous area.

Epoxy glue contains hazardous chemicals that can cause skin irritation, respiratory problems, and eye damage. Therefore, it is vital to wear protective gear such as gloves, safety goggles, and a respirator when handling epoxy glue. Additionally, working in a well-ventilated area and avoiding inhalation of fumes is crucial.

Moreover, it is important to keep the epoxy glue away from children and pets. The potential hazards of epoxy glue can be minimized by taking proper safety precautions. It is important to remember that prevention is better than cure. By following safety guidelines, you can avoid accidents and ensure a safe working environment.

Moving forward, it is essential to prepare the surface carefully before applying the epoxy glue.

Surface Preparation

Achieving a successful bond with epoxy adhesive requires meticulous surface preparation, which is crucial for ensuring the durability and longevity of the final product. Common mistakes often involve neglecting surface preparation, which can lead to a weak bond or even complete failure of the project.

The first step in surface preparation is to clean the surface thoroughly, removing any dirt, oil, or debris that may be present. Sanding the surface is also essential, as it helps to create a rough texture that the adhesive can adhere to. It is important to note that the surface should not be too smooth, as this can prevent proper bonding.

Best practices for surface preparation include using a clean and dry surface, allowing enough time for the surface to dry completely after cleaning, and ensuring that the surface is free from any contaminants.

In summary, taking the time to properly prepare the surface is essential for achieving a successful bond with epoxy adhesive, and neglecting this step can lead to costly mistakes and a weakened final product.

Moving forward, the next step in the process is mixing and application of the epoxy adhesive.

Mixing and Application

This section will discuss the key points of mixing ratio, applying epoxy glue, and curing time.

The mixing ratio is crucial as it affects the strength and durability of the bond.

Proper application techniques, including surface preparation, are necessary to ensure the epoxy glue adheres well.

Curing time varies depending on the type of epoxy glue used and the environmental conditions, and it is essential to follow the manufacturer’s guidelines for optimal results.

Mixing Ratio

The mixing ratio is an essential aspect to consider when utilizing epoxy, as it directly affects the chemical reaction and overall strength of the bond.

Common mistakes during mixing include inaccurate measurements and failure to mix thoroughly, resulting in a weak bond.

To avoid these mistakes, it is recommended to use digital scales to measure the exact amount of resin and hardener required, ensuring a 1:1 ratio for most epoxies.

Additionally, it is important to mix for the recommended time, typically around two to three minutes, and to scrape the sides and bottom of the container to ensure even mixing.

It is also crucial to use the mixture within the recommended pot life, which varies depending on the specific epoxy.

With precise measuring techniques and proper mixing, the resulting bond will be strong and durable.

When applying epoxy glue, it is important to follow the manufacturer’s instructions and use the appropriate tools for the specific project.

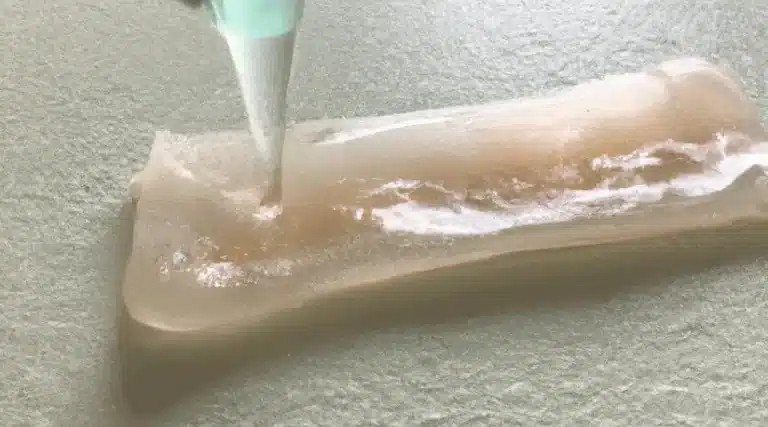

Applying Epoxy Glue

The process of applying epoxy involves a careful consideration of factors such as surface preparation, application technique, and curing time, all of which are critical to achieving a successful and long-lasting bond.

Epoxy glue application techniques vary depending on the project at hand, but it is important to apply the glue evenly and ensure that it covers the entire surface area. Common mistakes to avoid include spreading the glue too thin, failing to mix the components thoroughly, and not allowing enough time for the glue to cure.

It is also important to follow the manufacturer’s instructions and work in a well-ventilated area to avoid inhaling fumes. Once the epoxy has been applied, it is important to let it cure fully before handling the project. This typically takes anywhere from several hours to a few days, depending on the type of epoxy and the environmental conditions.

With proper application and curing, epoxy can create a strong and durable bond that will last for years to come. Moving forward, an understanding of curing time is crucial to ensuring the best possible results.

Curing Time

After discussing how to properly apply epoxy glue, the next important factor to consider is the curing time. This refers to the length of time it takes for the epoxy to fully harden and cure.

Factors affecting the curing time include the temperature and humidity of the environment, the type of epoxy used, and the thickness of the adhesive layer.

As a general rule, the curing time can range from a few hours to several days, depending on these factors. Troubleshooting common issues such as incomplete curing or yellowing can be addressed by adjusting these factors or using a different type of epoxy.

Understanding the curing time is crucial in achieving a strong and durable bond.

Moving forward, let us explore some tips and tricks for working with epoxy glue.

Tips and Tricks

This section provides valuable insights and techniques for optimizing the application of epoxy adhesive in a range of applications.

Proper storage is key to ensuring the epoxy remains in good condition, preventing it from hardening or becoming unusable. It is important to store the epoxy in a cool, dry place away from direct sunlight and extreme temperatures.

Troubleshooting is also an important aspect of using epoxy adhesive. If the epoxy does not cure properly, it could be due to incorrect mixing ratios or insufficient surface preparation. To avoid this, follow the manufacturer’s instructions carefully and ensure that the surfaces to be bonded are clean and dry.

Additionally, it is important to work in a well-ventilated area and wear protective gear such as gloves and goggles.

By following these tips and tricks, you can achieve optimal results when using epoxy adhesive in your projects.

In the next section, we will provide a conclusion and additional resources for further information.

Conclusion and Additional Resources

In conclusion, epoxy glue is a versatile and strong adhesive that can be used for a variety of projects. With proper preparation and application, it can provide long-lasting and durable bonds. However, it is important to note that epoxy glue may not be the best option for every project and there are alternative uses and other adhesives available.

For those looking for a more environmentally friendly option, there are now eco-friendly epoxies available. Additionally, it is always a good idea to compare the strength, drying time, and other characteristics of different adhesives before deciding which one to use for your project.

For those interested in learning more about epoxy glue and its uses, there are many resources available online, including tutorials and videos.

Conclusion

In conclusion, epoxy glue is a versatile adhesive that can be used for various projects. It is suitable for bonding different materials, including metals, plastics, and wood. However, proper surface preparation, mixing, and application are essential for achieving a strong bond. Additionally, it is crucial to observe safety precautions when working with epoxy glue.

Overall, the success of any epoxy glue project depends on the user’s knowledge, skills, and attention to detail. By following the guidelines in this comprehensive guide, one can confidently tackle any epoxy glue project with ease.

Remember to take your time, work in a well-ventilated area, and wear protective gear. With practice, you’ll become an expert in handling epoxy glue, and your projects will be the envy of all.

For additional resources, consult the manufacturer’s instructions or seek guidance from a professional.