Super glue is one of the most versatile and popular adhesives used today. It can be used to repair a variety of materials, from wood to plastic. But Does Super Glue Work On Rubber? This article will explore this question in detail, examining the benefits and drawbacks of using superglue on rubber.

For many people, using superglue offers a quick and easy solution for repairing broken items. Its fast-drying properties make it ideal for fixing problem areas quickly and effectively. As a result, it’s often seen as an ideal solution when one needs to fix something in a hurry.

Let’s dive into this peculiar topic and uncover the taste, health risks, and even unique uses of glue beyond its intended purpose.

However, before attempting to use superglue on rubber, there are some important considerations that must be taken into account. In this article we will take an in-depth look at the advantages and disadvantages of using super glue on rubber, so that you can make an informed decision about whether or not it’s right for your particular needs.

Does Super Glue Work On Rubber

Super glue is an adhesive substance used for bonding and fixing surfaces together. It is also known as cyanoacrylate glue, or simply CA glue. This type of glue has a strong bonding power that provides an immediate solution to a wide range of problems. With its powerful fixative properties, superglue can be used to repair broken objects, seal cracks, and stick items together. As the word ‘super’ suggests, this type of glue can create a bond that is typically stronger than most other glues.

Superglue offers many advantages over traditional glues such as its fast drying time and ease of use. It can be applied quickly and dries almost instantly due to its low viscosity. Additionally, the lack of fumes makes it safer to use compared to other types of adhesives. Superglue is also versatile because it sticks well to many different materials including plastics, rubber, metal and glass.

Considering all these desirable properties, it is no wonder that many industries and households widely use superglue. Its quick-fixing abilities make it the perfect tool for any situation that requires a strong bond in a short period of time. Moving forward, we’ll explore how effective superglue can be when used on rubber surfaces.

Advantages Of Using Super Glue On Rubber

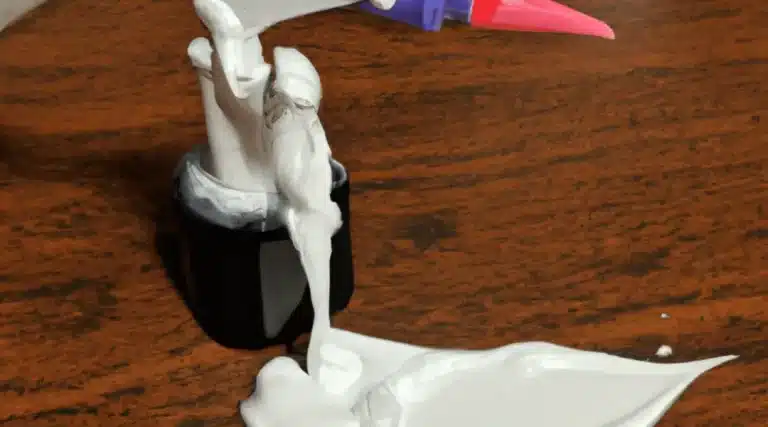

Using super glue on rubber is a great solution for many repair and bonding needs. This type of adhesive has several advantages over other binding agents, including quick-drying time, strong adhesion to rubber, and durability under extreme conditions.The adhesive creates an incredibly strong bond between the rubber and glue, making it suitable to repair broken or worn-down items. Super glue also offers superior protection against water, oil and heat damage.

In Terms Of Strength

In terms of strength, the rubber-glue bond created by super glue is very reliable and able to hold objects together in even the most demanding conditions. This means that you can use it for multiple applications without worrying about its ability to maintain a secure bond.Additionally, using super glue on rubber ensures that the repair will last for a long time without deteriorating or weakening due to weathering or heavy use.

Fast Drying Time Of Super Glue

The fast drying time of super glue makes it an ideal choice for situations where quick repairs are necessary. It only takes a few seconds for the glue to set so you don’t have to wait around for hours before being able to move onto another task or put the repaired item back into use. When you apply the glue, it creates a secure bond almost instantly, which eliminates any fear of the objects coming apart once they glued together.

Super glue is an excellent choice when it comes to repairing or bonding rubber materials due to its strength, durability and speed of drying. With its superior adhesion capabilities and long-lasting performance, this adhesive can help ensure that your repairs will stand up against even the toughest conditions while providing a safe and secure bond between two surfaces. Therefore, one should carefully consider the disadvantages of using super glue on rubber before pursuing this option.

Disadvantages Of Using Super Glue On Rubber

Using superglue on rubber can be an inadequate solution for some applications. The bond strength of the glue is not as strong as other adhesives and it may not hold up to the demands put on it. This means that any application of superglue to a rubber surface may not provide the desired result. Additionally, the glue does not adhere well to certain types of rubber and may peel off or separate from the surface over time.

Tendency To Hardening

The adhesive also has a tendency to harden quickly after application, which makes it difficult to adjust or reposition materials afterward. Moreover, while superglue can be used in outdoor environments, it is not designed to withstand extreme temperatures or harsh weather conditions. In these cases, using another type of adhesive is often more beneficial.

Finally, because superglue creates a strong bond between two surfaces, removing any excess glue can be challenging without damaging the surface underneath. This makes it important to follow best practices when applying the glue in order to avoid this problem.

Best Practices For Applying Super Glue On Rubber

Have you ever wondered if super glue works on rubber? Indeed, it can. However, it’s important to use the right technique to ensure your project will hold up and last. This section will discuss best practices for applying super glue on rubber safely and effectively.

First off, it’s important to choose the right type of super glue for your project. Super glues made specifically for rubber have special ingredients that make them adhere better than regular super glues. It’s also important to take into consideration the surface of the rubber you’re working with; some surfaces may require an extra step such as sanding before applying the glue.

Once you’ve chosen the right type of glue, practice safety by wearing protective gear such as gloves and eye protection when handling any type of adhesive product. Make sure there is adequate ventilation in the room where you are working and that it is free from flammable materials like paint or gasoline.

NOTE

It is important to apply the glue evenly across both surfaces that are being bonded together, as this helps ensure a strong bond. Allow ample time for each side to dry completely before joining them together – this could take anywhere from 10 minutes up to several hours depending on the brand of glue used and environmental conditions such as temperature and humidity levels. After joining both pieces together, press down firmly all around so that no air bubbles remain between them and allow several hours or overnight for a strong bond to form between them.

By following these steps, you can successfully apply super glue on rubber with confidence knowing that your project will stay in place! With proper care and attention, your projects made with super glue on rubber can last years without needing repairs or replacement parts.

Different Types Of Super Glues

Many different applications use super glue as a powerful adhesive. Its various types possess unique properties that can be helpful in determining the best-suited super glue for your project.

The most common types of super glue are waterproof and rubberized. Waterproof glue creates an airtight bond that won’t break if exposed to water or other liquids. Rubberized super glue is ideal for sealing rubber materials, as it creates a flexible bond that can withstand extreme temperatures and vibrations.

Flexible and instant-bonding super glues

Flexible and instant-bonding super glues are also available. After application, you can stretch and move flexible super glue, making it ideal for repairing items with flexible parts such as shoes or bags. Instant-bonding super glue requires no additional preparation and sets almost immediately after application. This makes it great for quick fixes or projects where time is important.

No matter which type of super glue you choose, make sure it’s capable of forming a strong bond with the material you’re using it on. To ensure this, you should test the bond strength of your chosen adhesive on a small patch of rubber before applying it.

How To Test The Bond Strength Of Super Glue On Rubber

Testing the bond strength of super glue when used on rubber can be a tricky endeavor. But by following a few simple steps, you can determine the gluing strength of your rubber-to-rubber bond. Let’s take a closer look:

- Pull the pieces apart: Use your fingers to carefully pull the two pieces of rubber apart. Pay attention to how much force it takes to break the bond so you can accurately gauge the gluing strength later.

- Visual inspection: Take a look at where the two pieces meet and check for any signs of separation or slipping. This will give you an idea of how secure and reliable the bond is between your rubber parts.

- Use a tension tester: If you want to measure exactly how strong your glue bond is, use a tension tester to apply pressure to the joint until it breaks apart. By doing this, you’ll get an accurate measurement of just how well your super glue has bonded these two pieces together.

With these three simple tests, you should have all the information you need about your super glue’s performance on rubber surfaces. Now that you know how well it holds up, let’s take a look at what to do if things don’t go according to plan and tips for removing super glue from rubber.

Tips For Removing Super Glue From Rubber

After testing the bond strength of super glue on rubber, it can be difficult to remove if it is not a successful bond. Removing super glue from rubber requires special techniques and materials to ensure that no damage is done to the rubber surface. Here are some tips for removing super glue from rubber.

Avoid using acetone on rubber as it may cause discoloration or damage. Try soaking the object in vinegar, soap and warm water, or an adhesive remover for 30 minutes before using a soft cloth or butter knife to remove the glue. If unsuccessful, consider using a commercial adhesive remover specifically designed for removing super glue from rubber surfaces.

To Avoid Damaging the Surface

To avoid damaging the surface, be gentle when removing adhesive from rubber. If alternative removal methods fail, consider applying additional adhesive layers or replacing the item. These options allow for a secure attachment without causing harm to the original surface.

Follow these tips to remove super glue from rubber surfaces without causing permanent damage. Explore other adhesive options that provide stronger bonds and easier removal as an alternative.

Alternatives To Using Super Glue On Rubber

Alternatives to super glue for bonding rubber include rubber cement, rubber sealant, rubber adhesives, tapes, and welding. These options offer a range of choices for creating strong bonds without the risks associated with using super glue.

Common Uses Of Super Glue On Rubber

When using super glue on rubber, consider potential disadvantages and alternatives. Super glue can be difficult to remove and may damage the surface. Alternatives specifically designed for rubber may provide stronger bonds and less risk. Weigh the pros and cons and explore all options to make an informed decision.

When working with super glue on rubber surfaces, it is important to understand the limitations of the material. Super glue is not designed to fill large gaps between two pieces of rubber or provide long-term protection from wear or tear. It also does not provide waterproof protection or any other type of protection against extreme temperatures. However, it does provide a strong bond between two pieces of rubber that can last for a long time if properly cared for.

Super GlueUsed As Sealant

In addition, super glue can be used as a sealant around edges and seams in order to protect them from moisture or other elements that may cause damage over time. This sealant helps keep out dust and contaminants while providing a secure bond that won’t easily break down due to pressure or force.

Note

When using this type of adhesive on a rubber surface it is important to clean the area thoroughly before application, as dirt and debris can interfere with the effectiveness of the bond. With proper care and maintenance, super glue can be an effective tool for repairing and protecting your rubber surfaces.

Safety Precautions When Working With Super Glue And Rubber

Working with super glue on rubber requires safety precautions. Wear protective gear. Ensure adequate ventilation. Avoid open flames. Apply small amounts of glue. Avoid contact with skin and clothing. Let the glue cure. Clean up excess glue promptly.

Wear protective gear: gloves and eyewear that cover your eyes completely. Work in a well-ventilated area to avoid exposure to fumes. Avoid open flames or sparks as they could ignite combustible vapors. Use small amounts of glue and avoid getting any on your skin or clothing. Let the glued area cure for several hours before handling. Clean up excess glue from surfaces as soon as possible.

Note

Apply small amounts of glue, avoid skin and clothing contact, wash affected areas with soap and water. Allow time to cure before handling and clean up excess glue with acetone to avoid damage. Following these safety precautions ensures successful and safe results when working with superglue and rubber.

Conclusion

Using Super Glue on rubber can be an incredibly useful tool for many projects. Its fast-acting and long-lasting bond is perfect for creating a strong, secure connection between rubber materials. It dries quickly, so the user can move on to their next task without delay. It also holds up in high temperatures, ensuring that the bond won’t break even under extreme conditions. The health risks associated with using Super Glue on rubber are minimal, making it a safe material to work with. Finally, it works well on all types of rubber, allowing users to easily create a robust bond when tackling any project.

Super Glue bonds rubber securely and quickly with minimal health risks. It’s an excellent adhesive due to its fast-acting, heat-resistant properties and consistent effectiveness on all types of rubber. With safety precautions, it’s perfect for DIY or professional projects.