Hot glue sticks are a common adhesive tool used in various industries, from crafting to manufacturing. These sticks are composed of a mixture of materials that are melted and then solidified when cooled, creating a strong bond between surfaces. Understanding the composition and materials used in hot glue sticks is essential in determining their effectiveness in a given application.

This article explores the basic components of hot glue sticks, including the additives used in their manufacture and their effects on the properties of the adhesive. Additionally, we will discuss the different types of hot glue sticks available and their advantages and limitations.

Lastly, we will provide tips for using hot glue sticks effectively, ensuring optimal performance and longevity. By the end of this article, readers will have a better understanding of the materials and composition of hot glue sticks, allowing them to make informed decisions when choosing an adhesive for their specific needs.

The Basic Components of Hot Glue Sticks

This section delves into the fundamental constituents of the adhesive tool commonly utilized in crafting and industrial settings. Hot glue sticks are composed of two primary components: thermoplastic polymer and a solidifying agent.

The manufacturing process involves melting the thermoplastic polymer to a liquid state, adding the solidifying agent, and then extruding the mixture into a cylindrical shape. When the hot glue stick is heated, the thermoplastic polymer softens and becomes tacky, allowing it to adhere to the desired surface. Chemical reactions occur within the solidifying agent, causing it to harden when cooled, creating a strong bond.

The exact composition of hot glue sticks may vary depending on the intended application. Additives may be included to alter the adhesive’s color, flexibility, or strength. The subsequent section will explore these additives and their effects.

Additives and Their Effects

The section delves into the effects of different polymer additives on the performance of hot glue sticks, providing a comprehensive understanding of the role these substances play in hot melt glue production.

Polymer additives are added to hot glue stick formulations to enable performance enhancement in areas such as tack, bond strength, and viscosity.

Some of the commonly used additives include plasticizers, which increase flexibility, and tackifiers, which provide better adhesion.

Other additives like waxes and antioxidants help to improve the stability and longevity of the adhesive.

Understanding the role of each additive is crucial in ensuring that hot glue sticks are manufactured to meet the desired performance requirements.

The next section will provide insights into how hot glue sticks are manufactured, detailing the processes and techniques used in the production phase.

How Hot Glue Sticks are Manufactured

The manufacturing process of thermoplastic adhesives involves the combination of different components in a controlled environment to achieve the desired adhesive properties. Hot glue sticks are manufactured using a similar process where the main components are a thermoplastic polymer, a tackifier, and a wax.

The thermoplastic polymer is melted and mixed with the tackifier and wax to achieve the desired viscosity, tackiness, and strength. The mixture is then extruded through a die and cooled to form a cylindrical shape. The hot glue stick is then cut into the desired length and packaged.

The manufacturing process plays a crucial role in determining the adhesive properties of the hot glue stick. The type of polymer used, the ratio of components, and the additives added can affect the bonding strength, curing time, and temperature resistance of the hot glue stick. Understanding the manufacturing process can help in selecting the appropriate hot glue stick for a specific application.

In the subsequent section, we will explore different types of hot glue sticks and their applications.

Different Types of Hot Glue Sticks

Hot glue sticks come in different types that cater to specific applications. Among these are high-temperature and low-temperature hot glue sticks, which are designed to work with varying heat levels.

Clear and colored hot glue sticks also offer versatility in terms of the visibility of the glue line. Additionally, specialty hot glue sticks such as glitter, glow-in-the-dark, and textured ones are available for more creative projects.

Understanding the different types of hot glue sticks is crucial in choosing the right one for the job.

High-Temperature vs. Low-Temperature

Distinguishing between high-temperature and low-temperature types of these adhesive products can significantly impact the success and durability of a given bonding application.

High-temperature hot glue sticks are best suited for bonding materials that require strong and durable bonds, such as metals, plastics, and ceramics.

Low-temperature hot glue sticks, on the other hand, are ideal for bonding materials that require flexibility, such as fabrics and foam.

When choosing between high-temperature and low-temperature hot glue sticks, it is important to consider the bonding strength vs. flexibility needed for the application. Other factors to consider include the melting point of the materials being bonded, the temperature of the environment in which the bonding will take place, and the application process itself.

Ultimately, the choice between high-temperature and low-temperature hot glue sticks will depend on the specific bonding needs of the project at hand.

Moving on to the next subtopic, clear vs. colored hot glue sticks offer their own unique advantages and disadvantages.

Clear vs. Colored

What advantages and disadvantages do clear and colored adhesive products offer, and how can their specific properties impact bonding applications?

Clear hot glue sticks are often preferred for bonding transparent or light-colored materials as they offer a nearly invisible bond. This is especially useful for crafts and DIY projects where aesthetics are important.

On the other hand, colored hot glue sticks provide a more visible bond and can be used to add a decorative touch to projects. Opaque colored hot glue sticks can be used to conceal imperfections or fill in gaps, while translucent colored hot glue sticks can enhance the appearance of colored materials.

However, colored hot glue sticks may not be suitable for bonding certain materials where the color of the adhesive may be visible or clash with the material being bonded. It is important to consider the specific properties of clear and colored hot glue sticks when choosing the appropriate product for a bonding application.

As we move into the next section about specialty hot glue sticks, we will explore the unique properties and applications of these products.

Specialty Hot Glue Sticks

Clear and colored hot glue sticks are popular among DIY enthusiasts and professionals alike, but specialty hot glue sticks offer unique formulations for specific applications. From high-temperature resistance to flexible bonding, specialty hot glue sticks are designed to meet the demands of specific projects.

Some examples of specialty hot glue sticks include foam-safe glue for use with polystyrene foam, wood-specific glue for woodworking projects, and even glitter glue for crafts. These specialized hot glue sticks offer a range of benefits and can make a significant difference in the outcome of a project.

Whether you’re working on a complex craft project or a professional construction job, specialty hot glue sticks can help you achieve superior results. Now let’s explore the advantages of hot glue sticks in more detail.

Advantages of Hot Glue Sticks

Hot glue sticks offer a multitude of advantages, including versatility, strong bonding properties, and quick drying time.

Versatility is a key feature of hot glue sticks, as they can be used on a variety of surfaces. Additionally, hot glue sticks form a strong bond that can withstand heavy loads and harsh environments.

Furthermore, hot glue sticks have a quick drying time, making them a convenient option for rapid assembly and repair.

Versatility

The versatility of the aforementioned adhesive products can be attributed to their ability to adhere to a wide range of surfaces and their capacity to serve as a bonding agent for various materials.

Hot glue sticks have been used in a variety of applications, from the traditional arts and crafts projects to more creative uses such as DIY repairs, jewelry making, and even in the fashion industry.

The adhesive can be applied to materials such as fabric, wood, plastic, and metal, making it a versatile solution for a range of projects.

Moreover, hot glue sticks can be used to create 3D objects by building layers of adhesive on top of each other, providing a new level of creativity and flexibility.

Additionally, hot glue sticks can be used to create temporary bonds that can be easily removed without causing damage to the underlying surfaces.

The versatility of hot glue sticks allows for a wide array of applications and creative uses, making it a popular choice among hobbyists and professionals alike.

This adaptability is further enhanced by the strong bonding properties of hot glue sticks, which will be discussed in the subsequent section.

Strong Bonding Properties

The adhesive’s remarkable bonding properties provide a powerful solution for a wide range of projects, allowing for a reliable hold that can withstand various stressors and environmental conditions.

Hot glue sticks are known for their excellent bonding ability, making them a go-to choice for many DIYers and professionals alike.

One of the key advantages of hot glue is its fast drying time, which allows for quick completion of projects.

Additionally, hot glue sticks are compatible with a variety of surfaces, including wood, metal, plastic, and fabric. This versatility makes it an ideal adhesive for many different applications.

Whether you are working on a home repair project or creating a craft, hot glue provides a strong and reliable bond that can stand up to the toughest conditions.

The fast drying time of hot glue will be discussed in the subsequent section without writing ‘step’.

Quick Drying Time

With its rapid drying time, hot glue sticks are a highly efficient solution for completing projects with speed and accuracy. The fast bonding and curing process allows for quick and easy application, making it ideal for those who want to get the job done quickly.

Additionally, the quick drying time means that there is less waiting around for the adhesive to set, which can save both time and frustration. For those who are working on time-sensitive projects or who simply want to maximize their productivity, hot glue sticks can be an invaluable tool.

However, while there are many benefits to using hot glue sticks, there are also limitations to consider.

Limitations of Hot Glue Sticks

One important consideration when working with hot glue sticks is to be aware of their limitations and potential drawbacks.

While hot glue sticks are known for their quick drying time, they may not be suitable for certain materials, such as those that are heat-sensitive or require a stronger bond.

Common problems with hot glue sticks include their tendency to dry out quickly or become brittle over time, which can lead to weakened bonds.

In such cases, alternative adhesives such as epoxy, super glue, or contact cement may be more effective.

However, hot glue sticks can still be a versatile adhesive option when used properly.

In the next section, we will discuss some tips for using hot glue sticks effectively without compromising their bond strength or integrity.

Tips for Using Hot Glue Sticks

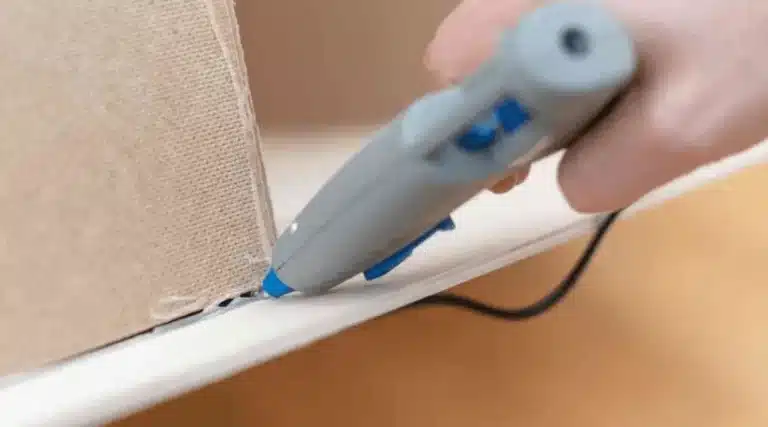

Uncovering the secrets to unlocking the full potential of this versatile adhesive requires a keen eye for detail and a touch of creativity, as hot glue sticks can serve as a powerful tool in the arsenal of any DIY enthusiast or professional.

When using hot glue sticks for crafts, it is important to keep in mind a few tips to ensure the best results.

Firstly, it is recommended to use a high-quality glue gun and glue sticks to avoid any common problems such as strings or weak bonds.

Secondly, it is important to work quickly and efficiently as hot glue dries fast and can become difficult to manipulate.

Additionally, it is recommended to use a heat-resistant surface to avoid any potential accidents.

Troubleshooting common hot glue problems such as uneven application or glue gun clogging can also be achieved by adjusting the temperature or cleaning the nozzle.

By following these tips, the full potential of hot glue sticks can be unlocked, allowing for endless possibilities in the world of DIY.

Conclusion

Hot glue sticks are widely used in various industries and applications due to their versatility and convenience. Understanding the composition and materials used in hot glue sticks is important to ensure its proper use and effectiveness.

The basic components of hot glue sticks are thermoplastic polymers, such as ethylene vinyl acetate and polyamides, which are responsible for its adhesive properties. Additives, such as stabilizers and tackifiers, are also incorporated into the hot glue stick formula to enhance its characteristics.

The manufacturing process of hot glue sticks involves melting the thermoplastic polymer and additives together, and then extruding it into the desired shape and size. Different types of hot glue sticks are available in the market, each with varying melting points, viscosity, and bonding strength.

Hot glue sticks offer several advantages, such as fast bonding, easy application, and compatibility with a wide range of materials. However, they also have limitations, such as low resistance to high temperatures and humidity, and poor bonding on smooth and non-porous surfaces.

In conclusion, hot glue sticks are a popular adhesive solution due to their ease of use and versatility. Understanding the composition and materials used in hot glue sticks is crucial for their proper application and performance. Hot glue sticks offer several advantages, but also have limitations.

Therefore, it is important to choose the right type of hot glue stick for the specific application and use it accordingly. As with any adhesive, proper storage and handling of hot glue sticks are also important for ensuring its effectiveness and longevity.