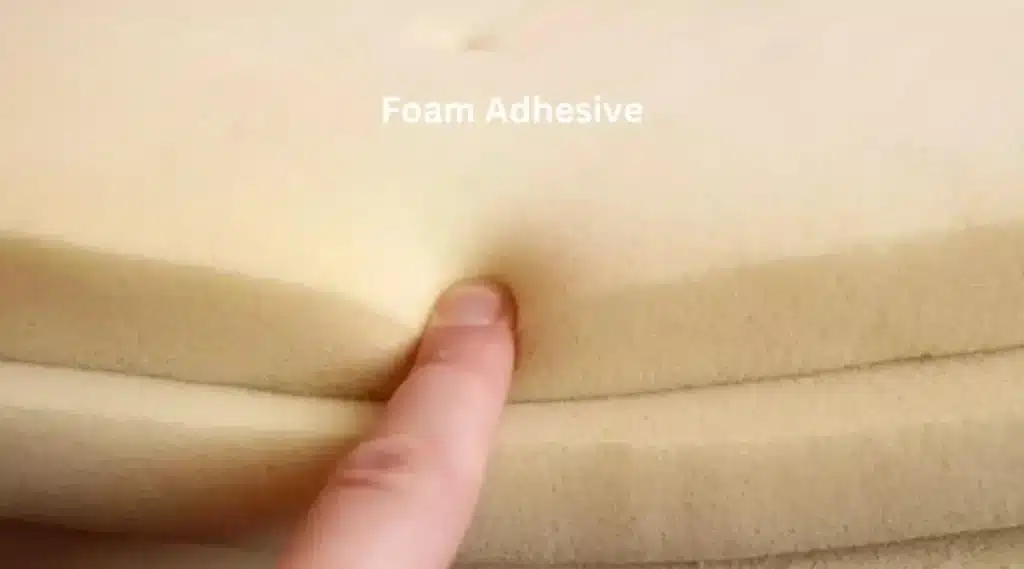

What is Foam adhesive? Foam Adhesive is a versatile and widely used bonding material that finds its applications across various industries and DIY projects. It is a type of adhesive that expands and cures into a foam-like structure, providing excellent bonding properties and insulation capabilities.

Let’s dive into this peculiar topic and uncover the taste, health risks, and even unique uses of glue beyond its intended purpose.

Whether you’re working on construction projects, automotive repairs, or simple household fixes, understanding foam adhesive and its different aspects is essential for achieving reliable and long-lasting results. How to Remove Glue from Eyelashes.

Types

- Single-Component Foam Adhesive: This type of foam adhesive comes in a pre-mixed and ready-to-use form, eliminating the need for mixing multiple components. It is ideal for small-scale projects and quick fixes.

- Two-Component Adhesive: This adhesive consists of two separate components that need to be mixed together just before application. Two-component foam adhesive offers better control over the curing process and is suitable for larger and more critical applications.

- Polyurethane Adhesive: Widely used in construction and automotive industries, polyurethane foam adhesive exhibits high strength, durability, and flexibility. It adheres well to various materials, including wood, metal, concrete, and plastic.

- Polystyrene Foam Adhesive: Specifically designed for bonding polystyrene materials, this adhesive prevents damage to the delicate foam surfaces.

- Silicone Foam Adhesive: Known for its high-temperature resistance and waterproof properties, silicone foam adhesive is often used in electronics and aerospace applications.

- Acrylic Foam Adhesive: This type of foam adhesive provides a strong bond and excellent weather resistance, making it suitable for outdoor applications.

Uses

Foam adhesive has a wide range of applications due to its unique characteristics and bonding capabilities. Let’s explore some common uses:

- Construction and Building Applications: Foam adhesive is widely employed in the construction industry for bonding insulation boards, drywall, and panels. It creates a seamless and airtight seal, enhancing the building’s energy efficiency.

- Automotive Industry Applications: In the automotive sector, foam adhesive is utilized for assembling components, such as door panels, roof liners, and interior trims. Its ability to dampen vibrations and reduce noise makes it a preferred choice for automotive manufacturers.

- DIY Home Projects: Foam adhesive simplifies various DIY tasks, such as fixing loose tiles, installing crown moldings, and sealing gaps and cracks around windows and doors.

- Electronics and Electrical Applications: The high-temperature resistance of silicone foam adhesive makes it suitable for bonding electronic components and providing electrical insulation.

- Marine and Aerospace Applications: This adhesive plays a crucial role in the marine and aerospace industries, where it is used to bond lightweight materials and ensure structural integrity.

Advantages

- Enhanced Bonding Performance: Foam adhesive forms a strong and reliable bond, surpassing conventional adhesives in performance.

- Increased Structural Integrity: By distributing stress across the bonded area, foam adhesive enhances the structural integrity of the materials it joins.

- Improved Energy Efficiency: Its thermal and sound insulation properties contribute to energy savings and a comfortable indoor environment.

- Reduced Vibration and Noise Transmission: Foam adhesive absorbs vibrations and reduces noise including in vehicles and appliances.

- Easy Application and Clean-up: Single-component foam adhesive is easy to apply, and any excess can be trimmed off after curing.

Disadvantages

- Potential Health Hazards: Some foam adhesives emit volatile organic compounds (VOCs) during curing. Which can be harmful if not used in a well-ventilated area.

- Limited Temperature Resistance: Foam adhesive may have temperature limitations, and extreme heat or cold can affect its performance.

- High Initial Cost: Compared to traditional adhesives, foam adhesive can be more expensive initially.

- Difficult Removal: Removing foam adhesive can be challenging, especially if it has fully cured.

- Limited Shelf Life: Two-component foam adhesive has a limited shelf life, and unused portions may become unusable over time.

How to Use Foam Adhesive Properly

Proper application of foam adhesive is crucial for achieving the desired results. Here are the essential steps:

- Surface Preparation: Ensure that the surfaces to be bond are clean, dry, and free from dust, grease, or other contaminants.

- Choosing the Right Foam Adhesive Type: Select the appropriate foam adhesive based on the materials to be bonding.

- Application Techniques and Tools: Follow the manufacturer’s instructions for application. Using a foam gun or nozzle to apply the adhesive evenly.

- Curing and Drying Process: Allow the adhesive to cure completely according to the recommended time. Avoiding any disturbance during the process.

Safety Precautions

- Personal Protective Equipment (PPE): Wear gloves, safety goggles, and a mask to protect yourself from potential hazards.

- Proper Storage and Handling: Store foam adhesive according to the manufacturer’s instructions, away from direct sunlight and extreme temperatures.

- First Aid Measures for Accidents: In case of accidental contact with skin or eyes, rinse thoroughly with water and seek medical attention if necessary.

- Disposal and Environmental Considerations: Dispose of any unused foam adhesive properly, following local regulations and guidelines.

Conclusion

Foam adhesive is a versatile and powerful bonding agent that offers numerous advantages, including enhanced bonding performance, improved energy efficiency, and reduced noise transmission. It comes in various types, each with its unique features and applications.

When using foam adhesive, it is crucial to follow proper application techniques and safety precautions. By understanding the different aspects of foam adhesive, you can make informed decisions and achieve excellent results in your projects, whether they are in construction, automotive, or DIY home improvements.