When it comes to repair and construction projects, having the right adhesive can make all the difference. Bonding putty adhesive is a versatile and reliable choice that has gained popularity in various industries.

Let’s dive into this peculiar topic and uncover the taste, health risks, and even unique uses of glue beyond its intended purpose.

This article will take you on a journey to explore the world of bonding putty adhesive, understanding its types, uses, pros, and cons. So, buckle up as we dive into the details of this fascinating adhesive solution!

Types of Bonding Putty Adhesive

Bonding putty adhesive comes in various formulations, each designed for specific applications. Let’s explore the most common types:

- Epoxy Putty: Known for its exceptional bonding strength, epoxy putty is a go-to choice for repairing metals, ceramics, and plastics. It is resistant to chemicals, making it ideal for sealing and bonding tasks.

- Silicone Putty: This flexible and durable adhesive is commonly used for sealing and waterproofing. It works well on glass, rubber, and metal surfaces, making it a preferred option for bathroom and plumbing repairs.

- Acrylic Putty: With quick curing time and excellent adhesion to porous materials like wood and concrete, acrylic putty is ideal for general repairs and bonding tasks.

- Polyurethane Putty: This type of putty adhesive offers excellent flexibility and is commonly used in automotive repairs and construction projects.

- Butyl Rubber Putty: With superior water resistance and weatherability, butyl rubber putty is commonly used for sealing and bonding in outdoor applications.

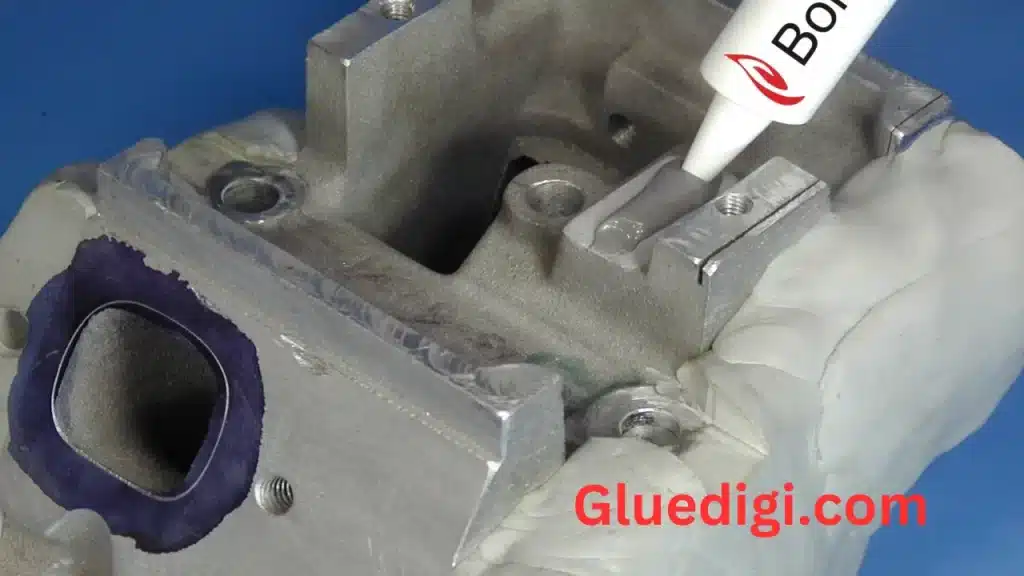

Understanding Bonding Putty Application

Before you dive into using it, it’s essential to know how to apply it correctly for the best results:

Preparing the Surface for Application

Ensure the surface is clean, dry, and free from dust and grease. A clean surface ensures better adhesion and a stronger bond.

Mixing and Handling Bonding Putty

Most bonding putty adhesives come in two parts that need to be mixed before application. Follow the manufacturer’s instructions for the correct mixing ratio and handling guidelines.

Techniques for Applying Bonding Putty

The application technique may vary depending on the type of bonding putty being used. Some may require kneading, while others can be applied directly with a spatula or putty knife.

Common Uses of Bonding Putty Adhesive

Bonding putty adhesive finds applications in various scenarios. Let’s explore its versatility:

Patching Cracks and Holes

Whether it’s fixing cracks in walls or filling in small holes in wooden surfaces, bonding putty adhesive can be a savior in repair projects.

Filling Gaps and Joints

Uneven gaps and joints between materials can be seamlessly filled with bonding putty, providing a smooth and even surface.

Bonding Different Materials

From bonding metal to plastic or glass to wood, this adhesive excels in creating strong and reliable bonds between different materials.

Sealing and Waterproofing

Bonding putty adhesive’s water-resistant properties make it an excellent choice for sealing gaps and preventing leaks in plumbing fixtures and outdoor structures.

Pros of Using Bonding Putty Adhesive

Bonding putty adhesive offers a range of advantages that make it a popular choice:

Versatility in Various Applications

The ability to work on various surfaces and materials makes bonding putty adhesive a versatile solution for different projects.

Strong and Durable Bonds

Once cured, bonding putty forms robust and long-lasting bonds, ensuring the durability of repairs and constructions.

Quick Setting and Curing Time

In time-sensitive projects, the fast-setting nature of bonding putty adhesive can significantly speed up the repair process.

Resistance to Temperature and Chemicals

Bonding putty’s ability to withstand extreme temperatures and resist chemicals makes it suitable for both indoor and outdoor applications.

Cons of Using Bonding Putty Adhesive

While bonding putty adhesive has many benefits, it also has some limitations to consider:

Limited Flexibility in Some Applications

In projects that require materials to flex and move, bonding putty may not be the most suitable option.

Potential Health Hazards

Some bonding putty adhesives may contain chemicals that can be harmful if not handled with care. Proper safety precautions should always be followed.

Not Suitable for Load-Bearing Applications

Bonding putty adhesive is not designed to bear heavy loads, so it’s essential to use it in non-structural applications.

Challenges in Removing and Replacing

In case of mistakes or repairs, removing cured bonding putty can be a challenging task, potentially damaging the surface.

Tips for Efficient Bonding Putty Application

To make the most of bonding putty adhesive, consider these tips:

- Ensure Proper Ventilation and Safety Measures: Work in a well-ventilated area and wear appropriate protective gear to prevent inhalation of fumes or skin contact.

- Choose the Right Type of Bonding Putty: Select the type of bonding putty that best suits your specific project needs for the best results.

- Surface Preparation Techniques: Properly clean and prepare the surface before application to ensure maximum bonding strength.

- Maximizing Bonding Strength: Follow the manufacturer’s guidelines for curing time and avoid stressing the bond until it is fully cured.

Tricks to Enhance Bonding Putty Performance

Take your bonding putty adhesive application to the next level with these tricks:

- Adding Fillers for Specific Applications: Incorporate fillers like glass beads or fibers to enhance bonding putty’s properties for specialized tasks.

- Using Primers for Difficult Surfaces: For challenging surfaces, using a primer can improve adhesion and ensure a stronger bond.

- Blending Different Types of Bonding Putty: Experiment with blending different putty types to achieve custom properties for unique applications.

- Post-Application Sealants and Coatings: Applying sealants or coatings after bonding putty application can enhance protection and aesthetics.

Best Practices for Storage and Handling

To ensure the longevity and effectiveness of bonding putty adhesive, follow these best practices:

- Proper Storage Conditions: Store bonding putty in a cool, dry place away from direct sunlight.

- Shelf Life and Expiry Considerations: Check the product’s shelf life and expiration date to use it within its optimal period.

- Avoiding Common Handling Mistakes: Avoid cross-contamination between the two parts of the bonding putty during handling and application.

Bonding Putty Adhesive vs. Other Adhesive Types

Let’s compare bonding putty adhesive with other common adhesive options:

Comparing with Glue and Tape

Unlike traditional glue or tape, bonding putty adhesive provides a stronger and more reliable bond, especially in demanding applications.

Advantages and Disadvantages in Different Situations

While bonding putty excels in versatile applications, specialized adhesives may outperform it in certain scenarios.

Case Studies: Real-Life Applications of Bonding Putty

Discover how bonding putty adhesive has been put to use in various real-life projects:

Construction and DIY Projects

From filling cracks in walls to sealing gaps in structures, bonding putty has become a staple in construction and DIY projects.

Automotive Repairs

Bonding putty adhesive is commonly used for fixing dents, cracks, and gaps in automotive bodies, providing a cost-effective repair solution.

Crafts and Artwork

Artists and hobbyists use bonding putty adhesive in their creative endeavors for its ease of use and reliability.

Environmental Impact of Bonding Putty Adhesive

As with any construction material, it’s essential to consider the environmental impact:

Sustainability and Eco-Friendly Options

Some manufacturers offer eco-friendly bonding putty options, promoting sustainability and reducing environmental impact.

Recycling and Disposal Methods

Properly dispose of any unused or expired bonding putty following local waste disposal guidelines.

Conclusion

Bonding putty adhesive is a versatile and reliable solution for various repair and construction projects. Its different types cater to specific needs, while its ease of use and quick curing time make it a favorite among DIY enthusiasts and professionals alike.

Remember to follow safety guidelines and consider the specific requirements of your project to make the most of this powerful adhesive. Whether you’re fixing a leaky pipe or crafting a masterpiece, bonding putty adhesive is here to help you get the job done efficiently and effectively. Happy bonding!