When it comes to bonding metals together, the use of traditional methods like welding and mechanical fastening is well-known. However, there is a lesser-known yet highly effective alternative Metal-To-Metal Adhesive. This adhesive provides a strong and durable bond that can withstand various stressors and environmental conditions.

Let’s dive into this peculiar topic and uncover the taste, health risks, and even unique uses of glue beyond its intended purpose.

In this article, we will explore the different types of metal-to-metal adhesives, their benefits, and drawbacks, along with real-life applications where they have proven their worth.

Understanding the Types of Metal-To-Metal Adhesives

Metal-to-metal adhesives come in various formulations, each catering to specific needs and requirements. Let’s take a look at the most common types:

Epoxy Adhesives

Epoxy adhesives are known for their exceptional bonding strength and versatility. They create a robust bond between metal surfaces and are widely used in industries like automotive, aerospace, and construction.

Polyurethane Adhesives

Polyurethane adhesives offer excellent flexibility and elongation properties, making them suitable for applications where there might be movement or vibrations.

Acrylic Adhesives

Acrylic adhesives are valued for their quick curing time and resistance to environmental factors, making them ideal for outdoor applications.

Anaerobic Adhesives

Anaerobic adhesives are specifically designed to cure in the absence of air, filling gaps and creating secure metal-to-metal bonds.

Cyanoacrylate Adhesives

Also known as super glue, cyanoacrylate adhesives provide rapid bonding for small metal components and are widely used in the electronics industry.

Silicone Adhesives

Silicone adhesives are known for their excellent resistance to high temperatures and are commonly used in automotive engines and electronic components.

Advantages of Metal-To-Metal Adhesives

Metal-to-metal adhesives offer several benefits over traditional joining methods:

High Strength Bonding

These adhesives provide robust bonding, distributing stress evenly across the surfaces, resulting in strong joints.

Enhanced Aesthetics

Unlike welding or screws, metal-to-metal adhesives create seamless bonds, improving the overall appearance of the assembled components.

Corrosion Resistance

Metal-to-metal adhesive bonds offer protection against corrosion by sealing out moisture and contaminants.

Flexibility in Design

With adhesives, manufacturers have more design freedom, as they can join dissimilar materials and work with intricate shapes and sizes.

Thermal Conductivity

Certain metal-to-metal adhesives retain excellent thermal conductivity properties, crucial in heat transfer applications.

Stress Distribution

Adhesives disperse stress evenly across the entire bonded area, reducing the likelihood of stress concentrations and subsequent failure.

Environmental Benefits

Using metal-to-metal adhesives often results in a reduction of material waste compared to traditional methods.

Limitations of Metal-To-Metal Adhesives

As with any bonding technique, metal-to-metal adhesives have their limitations:

Curing Time

The curing time for adhesives can be longer than desired, slowing down production processes.

Surface Preparation Challenges

Proper surface preparation is critical for successful bonding, requiring clean and well-prepared surfaces for optimal adhesion.

Temperature Sensitivity

Some metal-to-metal adhesives may not perform optimally in extreme temperatures.

Shear and Peel Strength Variability

The strength of the bond can vary depending on the specific adhesive used and the surface conditions.

Cost Considerations

Metal-to-metal adhesives can be more expensive than traditional joining methods, impacting production costs.

Applications of Metal-To-Metal Adhesive

The versatility of metal-to-metal adhesives makes them suitable for various industries and applications:

Automotive Industry

Metal-to-metal adhesives are commonly used in automotive assembly, reducing vehicle weight and improving fuel efficiency.

Aerospace and Aviation Sector

In the aerospace industry, adhesives play a vital role in bonding critical aircraft components, providing weight savings and improved aerodynamics.

Construction and Architecture

Metal-to-metal adhesives are use in construction to bond architectural elements, providing seamless joints and clean aesthetics.

Electronics and Electrical Components

These adhesives are essential in bonding electronic components, ensuring a reliable connection without damaging sensitive parts.

Industrial Equipment and Machinery

Metal-to-metal adhesives offer a viable alternative to welding and mechanical fasteners in various industrial applications.

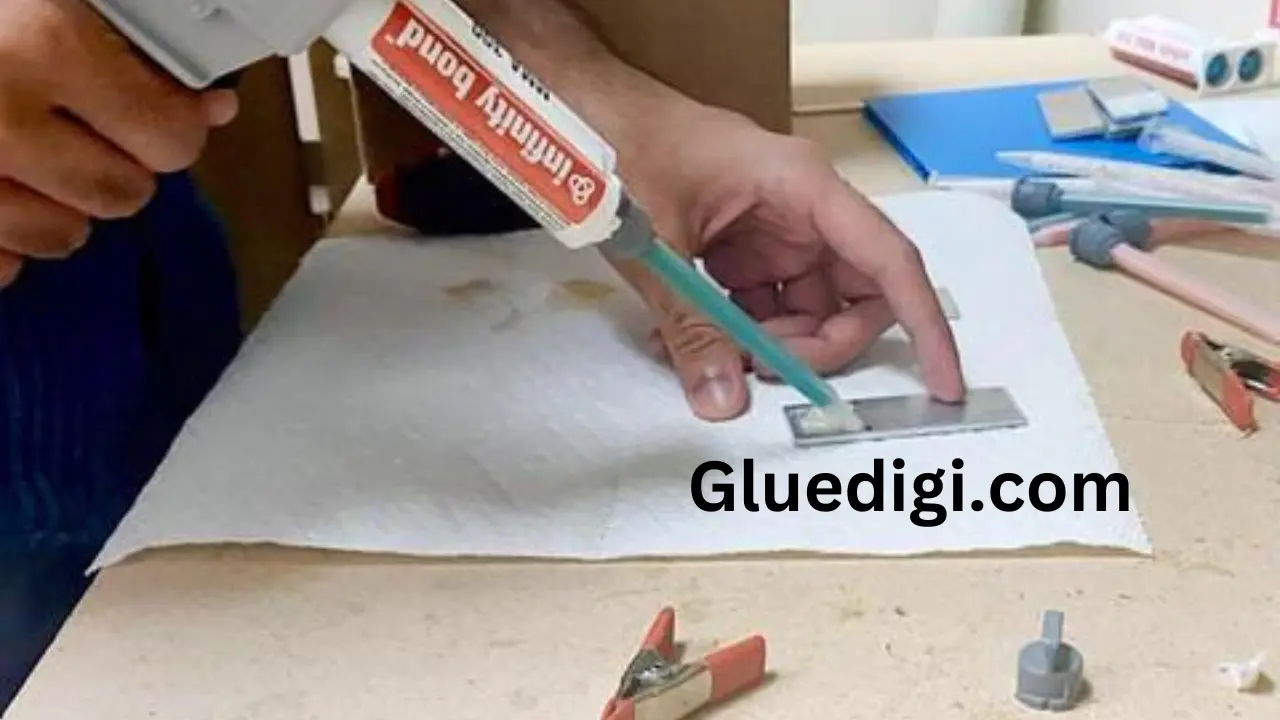

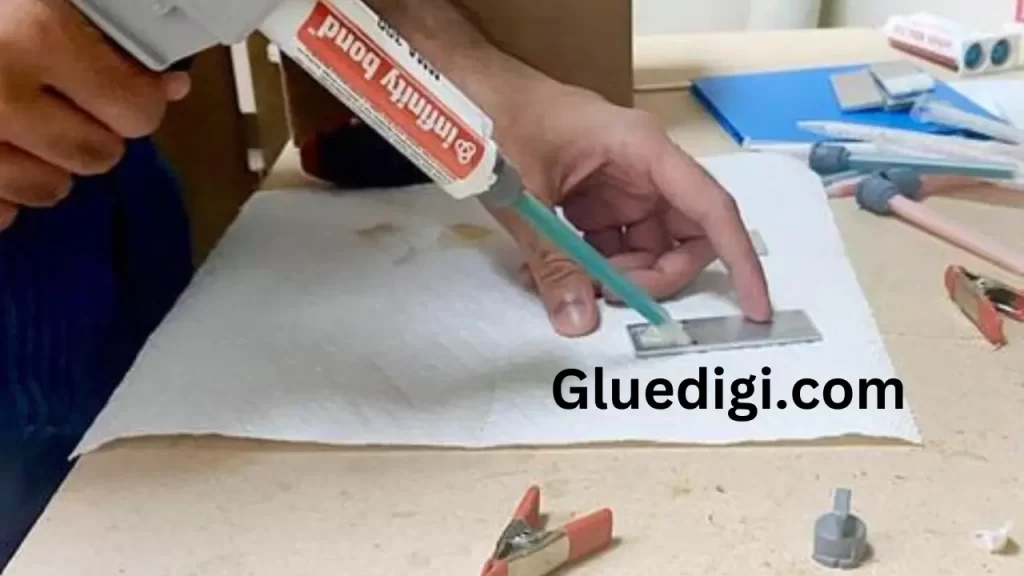

Exploring Tips for Using Metal-To-Metal Adhesives

To ensure the best results when using metal-to-metal adhesives, consider the following tips:

Surface Cleaning and Preparation

Thoroughly clean and prepare the surfaces to be bonding, ensuring they are free from contaminants like oil, grease, or rust.

Proper Mixing and Handling

Follow the manufacturer’s instructions for mixing and handling the adhesive to achieve the desired properties.

Joint Design and Alignment

Design the joint to ensure maximum contact between the metal surfaces for a strong bond, and align the components accurately during assembly.

Temperature and Humidity Considerations

Take into account the curing conditions specified by the adhesive manufacturer, especially concerning temperature and humidity.

Adhesive and Substrate Compatibility

Select the appropriate adhesive based on the types of metal to be bonded and their specific properties.

Tricks for Maximizing the Benefits of Metal-To-Metal Adhesives

Maximize the advantages of metal-to-metal adhesives with these practical tricks:

Hybrid Bonding Techniques

Combine metal-to-metal adhesives with other bonding methods to achieve even stronger joints for critical applications.

Enhancing Cure Speed

Use adhesives with shorter curing times when faster assembly is essential to improve production efficiency.

Joint Reinforcement Methods

Incorporate mechanical fasteners or reinforcements along with the adhesive for added strength.

Overcoming Common Challenges

Address surface preparation challenges proactively to ensure the adhesive performs optimally.

Real-life Examples of Successful Metal-To-Metal Adhesive Applications

Case Study 1: Automotive Lightweighting

In the automotive industry, metal-to-metal adhesives are instrumental in lightweight vehicles, reducing fuel consumption, and enhancing performance. Adhesive bonding enables the use of lighter materials while maintaining structural integrity.

Case Study 2: Aerospace Component Bonding

Aerospace manufacturers rely on metal-to-metal adhesives to bond critical components, such as wings and fuselage, ensuring a lightweight and aerodynamic design.

Conclusion

Metal-to-metal adhesives offer a compelling alternative to traditional bonding methods, providing high-strength joints, enhanced aesthetics, and improved design flexibility.

While they come with certain limitations, proper application and adherence to best practices can maximize their benefits. From automotive to aerospace, these adhesives have proven their value in various industries and continue to pave the way for innovative and efficient assembly techniques.