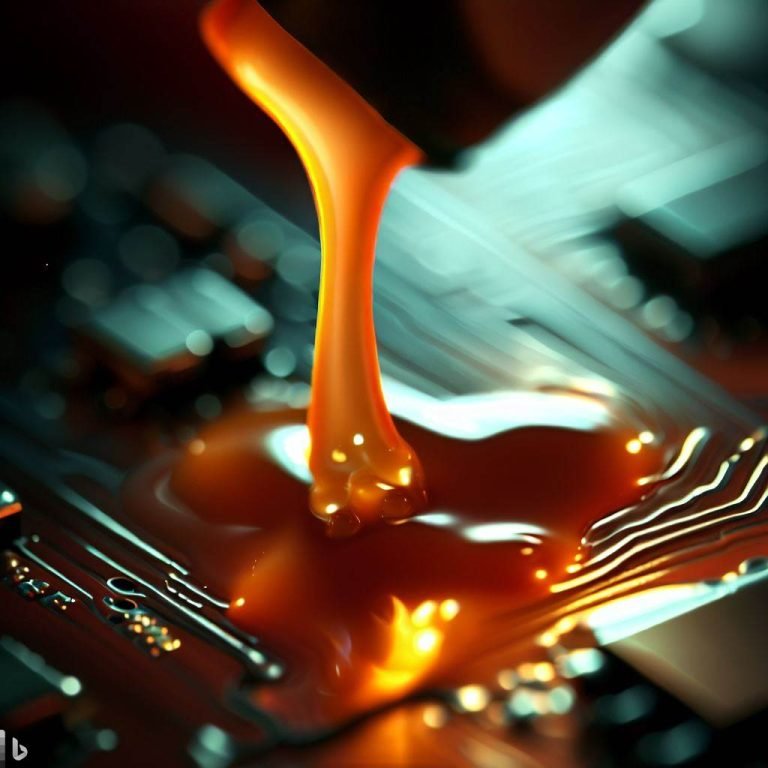

Thermally conductive adhesive is a highly versatile material that has become increasingly popular in the manufacturing industry. It is a specialized adhesive that is designed to conduct heat while bonding materials together, making it an excellent choice for applications where heat dissipation is important.

This adhesive is used in a wide range of industries, including electronics, automotive, aerospace, and medical industries, among others. As the demand for high-performance electronics and other applications grows, so does the need for innovative materials that can handle the heat generated by these products.

Thermally conductive adhesive is one such material that has been developed to meet this need. In this article, we will explore what thermally conductive adhesive is, its uses, advantages, and disadvantages, as well as factors to consider when choosing the best type for your application.

What is Thermally Conductive Adhesive?

The substance under examination is a bonding material characterized by its ability to transfer heat energy across its surface, often employed in scenarios where efficient heat dissipation is paramount.

Thermally conductive adhesive is a type of adhesive that is designed to provide thermal conductivity between two surfaces, while also bonding them together. It is used in a wide range of applications, including electronics, automotive, aerospace, and industrial manufacturing.

The benefits of using thermally conductive adhesive include its ability to transfer heat more effectively than traditional adhesives, its ability to reduce the risk of thermal damage, and its ability to improve overall system performance. Its application is also easy and convenient, making it an ideal solution for many industries.

Moving forward, we will explore the different uses of thermally conductive adhesive.

Uses of Thermally Conductive Adhesive

Thermally conductive adhesives have a wide range of applications across various industries. In the electronics industry, these adhesives are used to bond heat sinks onto microprocessors and other electronic components to enhance heat dissipation.

The automotive industry uses thermally conductive adhesives to attach sensors, control modules, and other electronic components to enhance their performance and reliability.

Similarly, the aerospace industry utilizes these adhesives to enhance the thermal management of avionics and other electronic systems.

Electronics Industry

It is certainly a coincidence that the electronics industry, which heavily relies on the efficient transfer of heat, has found a valuable solution in a material that is inherently sticky – thermally conductive adhesive. This adhesive has become a popular choice for bonding electronic components as it facilitates heat dissipation by providing a conductive path for heat to flow away from the source.

The following are some uses and advantages of thermally conductive adhesive in the electronics industry:

-

It provides a reliable and low-cost solution for attaching heat sinks to electronic devices.

-

It helps to reduce the operating temperature of electronic components by efficiently dissipating heat.

-

It eliminates the need for mechanical fasteners, improving the design flexibility of electronic devices.

-

It enables better thermal management in high-performance electronic devices such as CPUs, GPUs, and power amplifiers.

-

It improves the reliability and longevity of electronic devices by minimizing thermal stress and preventing hot spots.

With the increasing demand for high-performance electronic devices, the use of thermally conductive adhesive is expected to grow rapidly in the electronics industry.

Moving on to the next section, let’s explore how the automotive industry is benefiting from this remarkable material.

Automotive Industry

The intersection of the electronics and automotive industries has presented an opportunity for the incorporation of a material that facilitates heat dissipation, ultimately improving the performance and longevity of electronic components in vehicles.

Thermally conductive adhesive has been increasingly used in automotive applications due to its ability to bond and conduct heat simultaneously. This adhesive is commonly used in automotive electronics, such as LED lighting and control modules, as well as power electronic modules and battery cooling systems.

The benefits of using thermally conductive adhesive in automotive manufacturing include improved thermal management, reduced component size and weight, and increased reliability. However, challenges such as cost, compatibility with different materials, and long-term reliability need to be considered when using this adhesive.

In the subsequent section about the aerospace industry, we will explore the potential applications of thermally conductive adhesive in this field.

Aerospace Industry

The aerospace industry has been exploring innovative ways to enhance the safety, durability, and efficiency of aircraft components, and the incorporation of a material that can improve heat dissipation and bonding properties could be a significant breakthrough.

Thermally conductive adhesive has been used in space technology to bond and dissipate heat from electronic components, as well as in military equipment to enhance performance and durability.

This adhesive offers numerous benefits, including improved heat transfer, reduced weight, and increased design flexibility.

The use of thermally conductive adhesive can also reduce the need for mechanical fasteners, leading to simpler and more efficient manufacturing processes.

With its numerous applications and benefits, thermally conductive adhesive has the potential to revolutionize the aerospace industry and beyond.

Advantages of Thermally Conductive Adhesive

One notable benefit of thermally conductive adhesive is its ability to efficiently transfer heat, making it a preferred choice for applications where heat management is critical. Compared to traditional adhesives, this type of adhesive offers an improved efficiency in heat transfer, which helps to reduce the risk of overheating in electronic components.

Additionally, thermally conductive adhesives provide a reliable and long-lasting bonding solution for components that generate a significant amount of heat. This type of adhesive also helps to reduce the overall weight of a product by eliminating the need for bulky heat sinks or thermal pads.

In summary, the advantages of thermally conductive adhesive include efficient heat transfer, long-lasting bonding, and reduced weight. However, like any other product, thermally conductive adhesive has its own set of disadvantages that need to be considered.

Disadvantages of Thermally Conductive Adhesive

Thermally conductive adhesive comes with a few disadvantages that must be considered before deciding on its use. One of the major drawbacks is its limited bonding strength, which might not be suitable for applications that require high load-bearing capacities.

Additionally, removing the adhesive can be challenging, making it unsuitable for applications that require easy disassembly.

Lastly, the high cost of thermally conductive adhesive might not be feasible for some applications, especially those with a tight budget.

Limited Bonding Strength

The bonding strength of thermally conductive adhesives is a common concern among users, with strength limitations being a major disadvantage. Some studies report only 50% of the expected bond strength at elevated temperatures. For instance, a study by Fan et al. found that the shear strength of an epoxy-based thermally conductive adhesive decreased by 41% after exposure to 150°C for 500 hours.

This limited bonding strength makes it more difficult for the adhesive to withstand high temperatures, vibrations, and mechanical stress. Consequently, alternative adhesives with higher bonding strength or additional bonding methods may be necessary.

The subsequent section will discuss another disadvantage of thermally conductive adhesives, which is their difficulty to remove.

Difficult to Remove

Removing thermally conductive adhesives poses a challenge due to their strong bonding properties, which can cause damage to delicate substrates during removal. The adhesive is designed to create a strong bond between two surfaces, making it difficult to remove without causing damage.

The challenges of removal are further compounded by the fact that thermally conductive adhesives are often used in high-temperature applications, which can make them even harder to remove. Alternative solutions to removal challenges include using solvents or heat to soften the adhesive, but these methods also come with their own set of challenges.

Solvents can be harsh and may cause damage to the substrate, while heat can be difficult to control and may result in thermal damage. Despite these challenges, thermally conductive adhesives continue to be widely used due to their excellent thermal conductivity properties. The high cost of these adhesives is a consideration for many, but their performance benefits often outweigh the cost.

High Cost

While thermally conductive adhesives offer a range of benefits, one of their downsides is their relatively high cost compared to other types of adhesives. Cost considerations may be a significant factor when choosing a thermally conductive adhesive, especially for applications with high volume or where budgets are limited.

Alternatives comparison is crucial in determining whether thermally conductive adhesives are the best fit for the application. Factors such as the required thermal conductivity, operating temperature range, and bonding strength should all be considered.

Ultimately, selecting the right adhesive for a given application depends on a variety of factors, and careful consideration should be given to each before making a decision.

Factors to Consider When Choosing Thermally Conductive Adhesive

When selecting a thermally conductive adhesive, it is important to take various factors into account to ensure optimal performance and compatibility with the intended application. Here are some properties to evaluate before making a decision:

1) Thermal conductivity: the adhesive must have high thermal conductivity to effectively transfer heat from the source to the sink.

2) Adhesion strength: the adhesive must have strong bonding properties to ensure a reliable and long-lasting connection.

3) Chemical resistance: the adhesive must be resistant to the chemicals present in the application environment to prevent degradation and failure.

4) Curing time: the adhesive must have a curing time that is compatible with the production process.

By considering these factors, one can select the most appropriate thermally conductive adhesive for their specific application.

With this knowledge in mind, one can move on to the conclusion: is thermally conductive adhesive right for your application?

Conclusion: Is Thermally Conductive Adhesive Right for Your Application?

Now that we have discussed the factors that need to be considered when choosing thermally conductive adhesive, it is time to determine whether it is the right option for your application.

While it is an effective solution for heat dissipation, it is important to weigh the pros and cons of using it.

One of the main advantages of using thermally conductive adhesive is its cost effectiveness, as it is often less expensive than other options such as thermal grease or hardware solutions.

However, it may not be suitable for all applications and there may be alternative options that better suit your specific needs.

It is important to carefully evaluate your requirements and consult with experts to make an informed decision.

Conclusion

Thermally conductive adhesive is a type of adhesive that is designed to conduct heat while also bonding materials together. This type of adhesive is commonly used in electronic applications where heat dissipation is important, such as in LED lighting and power electronics.

The advantages of thermally conductive adhesive include its ability to create strong bonds and conduct heat effectively, while its disadvantages include its high cost and potential for thermal expansion.

When choosing a thermally conductive adhesive, it is important to consider factors such as the materials being bonded, the heat dissipation requirements, and the application method. It is also important to follow proper safety precautions when working with thermally conductive adhesive, as it can be harmful if ingested or inhaled.

In conclusion, thermally conductive adhesive can be a useful tool for those in the electronics industry who require strong bonds and effective heat dissipation. While it may not be suitable for every application due to its high cost and potential drawbacks, it is worth considering for those who require its unique properties. As the saying goes, ‘where there’s smoke, there’s fire,’ and in the world of electronics, effective heat dissipation is crucial for preventing damage and ensuring longevity.