Self-adhesive has revolutionized the way we approach various tasks that require bonding materials together. The invention of self-adhesive materials has replaced the traditional methods of using glue, tape, or other adhesives that require additional tools and time to apply. The simplicity and convenience of self-adhesive materials have made it a popular choice for various applications in industries such as construction, packaging, and printing.

Let’s dive into this peculiar topic and uncover the taste, health risks, and even unique uses of glue beyond its intended purpose.

Self-adhesive is a type of material that has an adhesive coating on one side, allowing it to stick to surfaces without the use of additional adhesives. This type of material is available in different types, such as tapes, films, labels, and stickers, each with different properties and applications.

The uses of self-adhesive materials are vast and varied, ranging from simple household tasks such as labeling and sealing envelopes to more complex tasks such as bonding components in the aerospace industry. Despite its popularity, self-adhesive materials have both pros and cons that must be considered before use.

Definition and Types of Self-adhesive

The term ‘self-adhesive’ refers to a type of material that is capable of sticking to surfaces without the need for additional adhesive agents, and can be categorized into several types based on their composition, application, and adhesive strength.

The most common types of self-adhesive materials include pressure-sensitive adhesives, heat-activated adhesives, and solvent-activated adhesives. Pressure-sensitive adhesives are the most widely used type of self-adhesive due to their ease of application, ability to adhere to a variety of surfaces, and low cost.

Heat-activated adhesives require heat to activate the adhesive properties and are commonly used in the automotive and aerospace industries. Solvent-activated adhesives require a solvent to activate the adhesive properties and are commonly used in the construction industry.

Self-adhesive materials have a wide range of applications, including packaging, labeling, graphic design, and construction. They are commonly used in the packaging industry to seal boxes and bags and provide a tamper-evident seal.

Overall, the versatility and convenience of self-adhesive materials make them a popular choice in many industries.

Moving on to the uses of self-adhesive, these materials are highly valued for their ability to simplify and streamline various processes, as well as their flexibility and versatility.

Uses of Self-adhesive

1. Product Labels and Stickers

Self-adhesive materials are widely used to create labels and stickers for products, packages, and various items. They provide easy application and can be customized with important information, branding, or warnings.

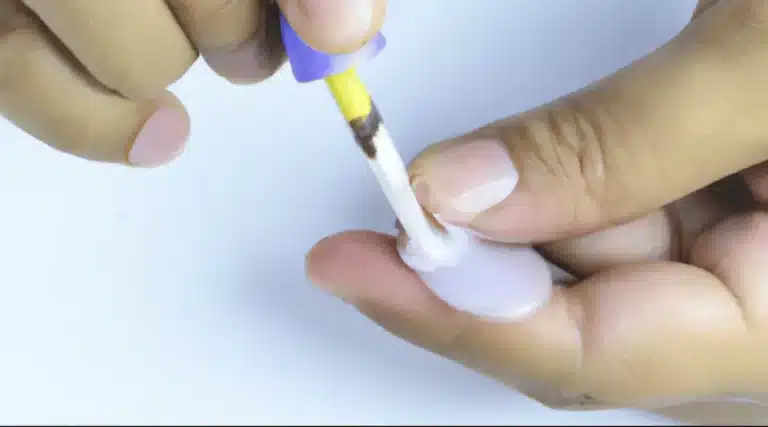

2. Bonding and Sealing with Tapes

Self-adhesive tapes, such as duct tape, electrical tape, and masking tape, are extensively used for bonding, sealing, and marking purposes in both domestic and industrial settings.

3. Decals and Graphics

Self-adhesive materials are used to create decals and graphics for vehicles, windows, walls, and various surfaces, providing a cost-effective and easy-to-apply alternative to traditional paint or printing methods.

4. Posters and Signage

Self-adhesive materials serve as an excellent medium for creating posters, signs, and displays that can be easily affixed to walls, doors, and other surfaces.

5. Stationery and Craft

In stationery and crafting, self-adhesive materials are use to create interactive elements, such as removable notes, photo albums, and scrapbooks.

6. Packaging and Sealing

Self-adhesive materials are widely use in packaging applications to seal boxes, envelopes, and other containers securely.

7. Medical Applications

Self-adhesive bandages and medical tapes are commonly use to secure dressings, providing a simple and effective way to protect wounds and aid in the healing process.

8. Tacking and Mounting

Self-adhesive materials, like double-sided tape or mounting squares, are use for temporarily tacking or mounting lightweight objects, posters, or photographs.

9. Bookbinding

In bookbinding, self-adhesive materials are use to attach covers and bind pages together, providing a durable and efficient method.

10. Household and DIY Projects

Self-adhesive materials find numerous applications in DIY projects, home renovations, and repairs, serving as a quick and easy solution for various tasks.

Pros of Using Self-adhesive

Easy Application

Self-adhesive materials offer a straightforward application process. The adhesive backing eliminates the need for additional glues or tapes, making it quick and efficient. This ease of application saves time and reduces the complexity of various tasks.

Customizable

Self-adhesive materials can be easily customize to meet specific requirements. They can be printed with logos, information, graphics, or warnings, making them ideal for labeling, branding, and decorative purposes.

Versatility

Self-adhesive materials are highly versatile and can adhere to various surfaces, including paper, plastic, glass, metal, and more. This adaptability allows them to be used in a wide range of industries and applications.

Clean and Neat

Using self-adhesive materials eliminates the mess associated with traditional glues or tapes. There’s no risk of spillage or smudging, resulting in a clean and neat application process.

Removable and Repositionable

Many self-adhesive materials are design to be removable and repositionable, making them ideal for temporary applications or adjustments. Users can easily reposition or remove the material without leaving residue or causing damage to the surface.

Cost-Effective

Self-adhesive materials are often cost-effective compare to other bonding or labeling methods. Their ease of use and minimal waste during application contribute to cost savings for businesses and consumers.

Time-Saving

The quick and simple application process of self-adhesive materials saves time and increases overall efficiency in various projects, both in personal and professional settings.

Wide Range of Applications

Self-adhesive materials find applications in numerous industries, including packaging, stationery, automotive, construction, medical, and more. Their diverse uses showcase their adaptability in addressing different needs.

Secure Bonding

When applied correctly, self-adhesive materials provide a strong and secure bonding between surfaces, ensuring that labels, decals, or tapes stay in place over time.

Convenience and Portability

Self-adhesive materials are often available in portable formats, such as rolls or sheets, making them convenient to carry and use wherever needed.

Using self-adhesive materials offers a plethora of advantages, making them a popular choice for various projects and applications.

Cons of Using Self-adhesive

1. Limited Reusability

Self-adhesive materials often have a one-time application, and once they are stuck in place, they can be challenging to remove without causing damage to the surface they were attached to. Unlike traditional adhesives that can be easily repositioned or removed, self-adhesive products may lose their adhesive properties or leave behind residue, making them less suitable for reuse.

2. Environmental Concerns

Many self-adhesive products are made from synthetic materials, such as plastics or vinyl. The production and disposal of these materials can contribute to pollution and waste, potentially adding to the growing environmental crisis. As sustainability becomes a growing concern, using self-adhesive materials may not align with eco-friendly practices.

3. Limited Durability

The adhesive strength of self-adhesive materials can vary widely, and some may not provide the same level of durability as traditional methods like sewing, welding, or using mechanical fasteners. In applications where long-term bonding or high-strength adhesion is required, self-adhesive solutions may not be the most reliable choice.

4. Temperature and Moisture Sensitivity

Self-adhesive products can be sensitive to environmental factors, such as temperature and moisture. Extreme heat or cold can weaken the adhesive bond, leading to the detachment of the material. Similarly, exposure to moisture or humidity might cause the adhesive to lose its effectiveness, making it unsuitable for certain outdoor or wet environments.

5. Surface Compatibility Issues

Self-adhesive materials may not adhere well to certain surfaces, particularly those with rough, uneven, or non-porous textures. Before using self-adhesive products, it’s essential to ensure that the surface is clean, dry, and suitable for bonding. Failure to do so can result in a weak bond or complete failure of the adhesive.

6. Difficulties in Removal

While self-adhesive materials are designing to stick securely, removing them can be challenging and time-consuming, especially if they have been in place for an extended period. The process of removing self-adhesive products may require the use of solvents or other chemicals, which can further contribute to environmental concerns.

7. Limited Application Range

Self-adhesive materials may not be suitable for all types of projects or applications. For instance, they might not work well in high-temperature environments, under heavy loads, or in situations where dynamic movements are involve. In such cases, alternative bonding methods may be more appropriate and reliable.

Recommendations for Using Self-adhesive

1. Surface Preparation

Before applying self-adhesive materials, ensure that the surface is clean, dry, and free from dust, grease, or any other contaminants. Proper surface preparation is crucial for achieving a strong and long-lasting bond. If necessary, use appropriate cleaning agents or primers to enhance adhesion.

2. Test on a Small Area

If you’re using self-adhesive for the first time or on a new surface, it’s advisable to test the material on a small, inconspicuous area first. This will allow you to assess its adhesion properties and ensure it works well with the specific surface material.

3. Temperature and Moisture Considerations

Be mindful of the environmental conditions during application. Extreme temperatures can affect the adhesive’s performance, so avoid applying self-adhesive materials in excessively hot or cold environments. Additionally, ensure that the surface is dry, as moisture can compromise the adhesive bond.

4. Apply Even Pressure

To achieve a secure bond, apply even pressure over the entire surface of the self-adhesive material after application. You can use a roller or simply press down firmly with your hands. This step helps eliminate air bubbles and ensures maximum contact between the adhesive and the surface.

5. Gradual Application (for larger pieces)

For larger self-adhesive pieces, consider applying the material gradually, section by section. This approach minimizes the risk of misalignment and makes it easier to manage the application process, especially for intricate or detailed designs.

6. Reusability and Repositioning

If the self-adhesive material allows for repositioning, take advantage of this feature during application. It’s helpful to have a second pair of hands to assist in aligning and adjusting the material until you achieve the desired positioning. This is particularly useful for intricate designs or when working with irregularly shaped surfaces.

7. Follow Manufacturer’s Instructions

Always follow the manufacturer’s instructions and guidelines provided with the self-adhesive product. This includes recommendations on application techniques, storage conditions, and any specific precautions to take during the bonding process.

8. Consider Alternative Adhesive Methods

While self-adhesive materials are convenient, they may not always be the best choice for every application. Depending on the project’s requirements, consider alternative adhesive methods like sewing, welding, or mechanical fasteners for improved durability and longevity.

9. Store Properly

If you have leftover self-adhesive materials, store them in a cool, dry place, and ensure the packaging is properly sealed to maintain their adhesive properties. Proper storage can extend the material’s shelf life and preserve its effectiveness for future use.

10. Safety Precautions

Finally, be cautious when working with self-adhesive products, especially those that require the use of solvents or chemicals during application or removal. Follow safety guidelines, use protective equipment if necessary

Conclusion

Self-adhesive technology has become a game-changer in various industries, offering a convenient and efficient solution for bonding applications. Its ease of use and versatility have made it a popular choice for both professionals and consumers alike.

The ability to adhere to various surfaces without the need for additional adhesives simplifies tasks and reduces mess. Self-adhesive products have found applications in packaging, crafting, construction, and even medical fields.