Fast-drying adhesive is a type of glue that dries quickly, making it an ideal option for various applications. It is a popular choice for many industries, including construction, automotive, and woodworking, due to its ability to bond materials efficiently and effectively.

Fast-drying adhesive is widely used in the manufacturing process of products such as furniture, automotive parts, and electronics.

In this article, we will explore the definition of fast-drying adhesive, its uses, advantages, and disadvantages. We will also discuss the factors to consider when choosing fast-drying adhesive and safety precautions when using it.

By the end of this article, you will have a better understanding of fast-drying adhesive and how it can be beneficial in your projects or manufacturing processes.

Definition of Fast-drying Adhesive

Understanding the definition of a rapid-curing bonding agent is crucial in comprehending its utility in various industrial, commercial, and residential applications.

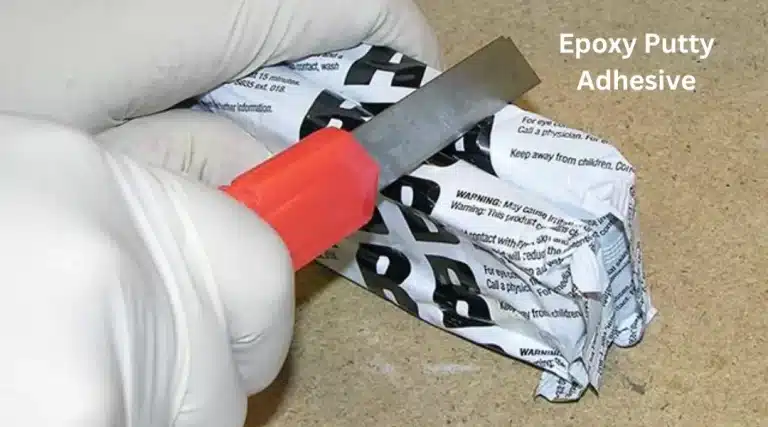

Fast-drying adhesive is a type of glue that cures quickly, typically in a matter of seconds or minutes, depending on the chemical composition and application method. This type of adhesive can be made from a variety of materials, including cyanoacrylate, epoxy, or acrylic. The chemical composition plays a significant role in determining the strength, durability, and versatility of the adhesive.

Some of the best brands in the market include Gorilla Super Glue, Loctite Super Glue, and Krazy Glue. These brands offer a range of fast-drying adhesives that cater to different applications and surfaces.

With this knowledge of the chemical composition and top brands of fast-drying adhesive, we can explore its many uses and benefits in various industries.

Uses of Fast-drying Adhesive

The practical applications of the adhesive’s quick bonding properties have garnered significant attention from various industries, making it a highly sought-after solution for efficient and reliable bonding.

Industrial applications, such as in manufacturing, construction, and automotive industries, have taken advantage of its fast-drying capabilities to improve productivity and assembly line efficiency.

DIY projects, from home repairs to crafting, have also benefited from its ease of use and quick results.

Fast-drying adhesive has become a versatile solution for a wide range of bonding needs.

In the subsequent section, we will discuss the advantages of using fast-drying adhesive.

Advantages of Fast-drying Adhesive

Efficiency, reliability, and versatility are just a few advantages that make fast-drying adhesive a popular choice for a variety of industries and DIY projects. The following are some advantages of fast-drying adhesive:

-

Saves time: Fast-drying adhesive provides quick bonding, which saves a lot of time. It eliminates the need to wait for a long time for the adhesive to dry, which is beneficial for industries that require fast-paced production.

-

Strong bonding: Fast-drying adhesive provides a strong bond, which makes it ideal for applications where the adhesive needs to hold up under pressure or weight.

-

Easy to use: Fast-drying adhesive is easy to use, as it can be applied with a brush, spray, or nozzle, depending on the application. This makes it ideal for DIY projects where people may not have professional tools or experience.

Overall, fast-drying adhesive offers numerous advantages for various applications. However, it is important to consider the potential disadvantages before using it.

Disadvantages of Fast-drying Adhesive

One must consider potential drawbacks when using fast-drying adhesive, as it may not bond as well to certain materials and can have a short shelf life. While it is ideal for quick fixes and urgent repairs, it may not be suitable for long-term use. Alternatives to fast-drying adhesive, such as two-part epoxy and cyanoacrylate, may provide a stronger and more durable bond.

Additionally, fast-drying adhesive can pose health hazards if not used properly, as the fumes can be toxic and cause respiratory problems. Therefore, it is important to use it in a well-ventilated area and wear appropriate protective gear.

It is crucial to weigh the pros and cons before deciding to use fast-drying adhesive. In the subsequent section about factors to consider when choosing fast-drying adhesive, we will explore these issues further.

Factors to Consider When Choosing Fast-drying Adhesive

When selecting a fast-drying adhesive, it is important to consider various factors to ensure optimal performance and reliability. Brand options should be researched thoroughly to determine the best option for the specific application.

Compatibility with the materials to be bonded is crucial, as some adhesives may not work well with certain materials. Application techniques should also be considered, as some adhesives require specific application methods to achieve the desired results.

Additionally, the conditions under which the adhesive will be used, such as temperature and humidity, should be taken into account, as this can affect the adhesive’s ability to bond effectively. Finally, the adhesive’s ability to withstand stress and strain is a crucial factor to consider, especially when bonding materials that will be subjected to regular use or movement.

It is important to carefully evaluate these factors before selecting a fast-drying adhesive to ensure that it will meet the specific needs of the application.

Moving forward, safety precautions when using fast-drying adhesive should also be taken into consideration.

Safety Precautions When Using Fast-drying Adhesive

To ensure safe use of fast-drying adhesive, it is important to be aware of the potential hazards and to follow proper safety protocols, which will be discussed in this section. Safety measures should always be taken when handling fast-drying adhesives, as they can be harmful if inhaled, ingested, or come into contact with the skin or eyes.

It is recommended to wear protective gloves, goggles, and a mask to prevent any accidents. Additionally, it is crucial to always use fast-drying adhesive in a well-ventilated area to avoid inhaling the fumes. Handling techniques should also be carefully observed, such as avoiding smoking or any heat sources that can ignite the adhesive, ensuring that the lid is tightly closed after use, and storing it in a safe and secure place out of reach of children and pets.

By following these safety precautions, potential accidents can be minimized, and the use of fast-drying adhesive can be done with ease and confidence. Moving forward, it is important to consider the pros and cons of using fast-drying adhesive in the next section.

Conclusion and Recommendation

In conclusion, after considering the potential hazards and safety measures required, it is recommended that one carefully weighs the benefits and drawbacks of utilizing fast-drying adhesive for DIY projects.

While this powerful tool has numerous advantages, including its quick bonding time and versatility in a variety of materials, it also has its cons, such as its strong smell and potential health hazards if not used with proper caution.

Additionally, when comparing fast-drying adhesive to traditional glue for quick fixes, it is important to note that the former may not be the best option for certain materials or projects.

Ultimately, it is up to the individual to determine whether the benefits outweigh the potential risks, but it is important to approach the use of fast-drying adhesive with caution and proper safety protocols.

Conclusion

Fast-drying adhesive is a type of adhesive that dries quickly, making it ideal for projects that require a fast turnaround time. It is commonly used in the automotive, construction, and electronic industries, among others.

Its advantages include its ability to bond different materials, its durability, and its resistance to water and heat. However, it also has its disadvantages, such as its strong odor and the fact that it can be difficult to remove once it has dried.

When choosing a fast-drying adhesive, it is important to consider factors such as the type of materials being bonded, the application method, and the environment in which it will be used. Safety precautions should also be taken when using fast-drying adhesive, such as wearing protective gear and working in a well-ventilated area.

In conclusion, fast-drying adhesive is a versatile and useful adhesive that has its benefits and drawbacks. As with any adhesive, it is important to choose the right type for your project and take safety precautions when using it. As the saying goes, ‘measure twice, cut once’ – taking the time to carefully consider your adhesive choice can save you time and money in the long run.