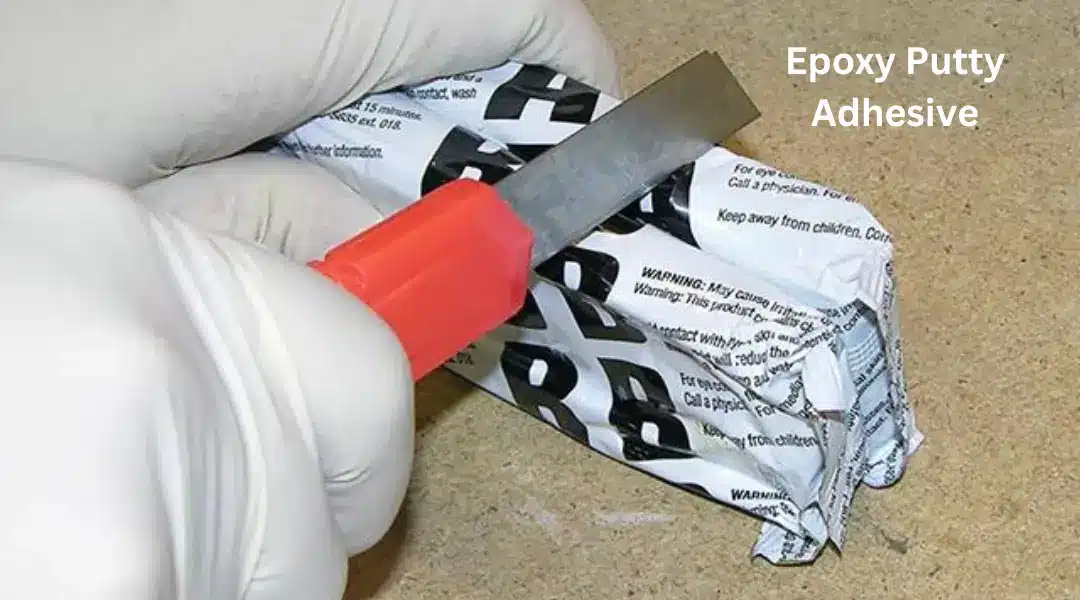

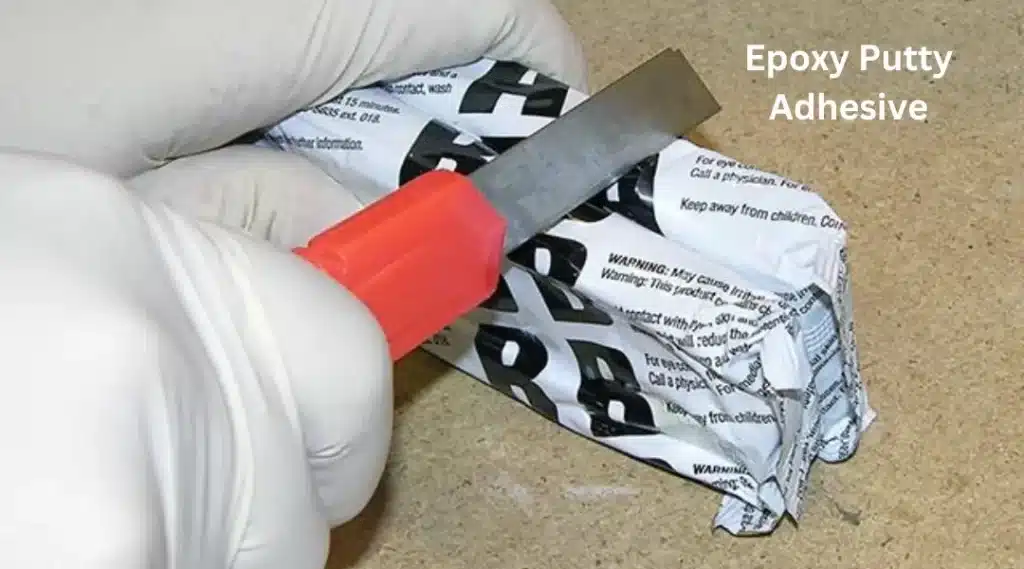

The Epoxy putty adhesive is a versatile and powerful bonding agent that has gained popularity across various industries due to its exceptional adhesive properties. It is a two-part adhesive that consists of a resin and a hardener. When these components are mixed, a chemical reaction occurs, creating a strong, durable bond that can withstand a wide range of conditions.

Let’s dive into this peculiar topic and uncover the taste, health risks, and even unique uses of glue beyond its intended purpose.

How Epoxy Putty Adhesive Works

The epoxy putty adhesive works through a process called polymerization. When the resin and hardener are combined, they begin to react and form long chains of molecules. This process generates heat and causes the mixture to harden and solidify. The cured epoxy putty creates a strong bond between surfaces, making it ideal for repairs and various applications.

Importance of Epoxy Adhesive in Various Industries

Epoxy putty adhesive is an indispensable tool in a multitude of industries. From household repairs to heavy-duty industrial applications, its unique properties make it a go-to solution for many bonding needs. Whether you’re fixing a leaking pipe or reinforcing metal parts, it offers a reliable and long-lasting solution.

Types of Putty Adhesive

It come in various types, each designed to cater to specific needs. Understanding the different types will help you choose the most suitable one for your project.

Single-Component Epoxy Adhesive

Single-component comes pre-mixed and ready to use. It offers convenience and ease of application, making it ideal for small-scale repairs and quick fixes. This type is perfect for filling gaps, cracks, and holes in different materials.

Two-Component Epoxy Putty Adhesive

Two-component epoxy putty adhesive requires mixing the resin and hardener in precise proportions. While it demands more preparation, it offers superior bonding strength and durability. This type is commonly used in heavy-duty applications and industrial settings.

Heat-Resistant Epoxy Putty Adhesive

Heat-resistant epoxy putty can withstand high temperatures, making it suitable for applications where other adhesives might fail. It is commonly used in automotive repairs, where parts are exposed to engine heat and friction.

Underwater Epoxy Putty Adhesive

The underwater adhesive is specially formulated to bond surfaces even in wet conditions. This type is perfect for repairing pipes, aquariums, and other items submerged in water.

Pros of Epoxy Putty Adhesive

Epoxy putty adhesive offers an array of benefits that make it a top choice for bonding solutions. Let’s explore the ten key advantages of using it

- Exceptional Bonding Strength: Epoxy putty adhesive creates an incredibly strong bond between materials, ensuring long-lasting and reliable results.

- Versatile and Multipurpose: From household repairs to heavy-duty industrial applications, this can be used on various surfaces and materials.

- Fast Curing Time: Depending on the type, it can cure rapidly, allowing for quick repairs and reduced downtime.

- High-Temperature Resistance: Heat-resistant epoxy putty adhesive can withstand extreme temperatures, making it suitable for applications where other adhesives might fail.

- Excellent Chemical Resistance: This highly resistant to various chemicals, ensuring durability in harsh environments.

Cons of Epoxy Putty Adhesive

While epoxy putty adhesive offers numerous advantages, it also has some limitations that users should be aware of.

- Limited Working Time: Some types of epoxy putty adhesive have a short working time, requiring quick and precise application.

- Mixing Complexity for Two-Component Adhesives: Two-component epoxy putty adhesive demands accurate mixing ratios, which can be challenging for beginners.

- Potential Health Hazards: During the application, it may release harmful fumes, so proper ventilation and personal protective equipment are necessary.

- Not Ideal for Flexible Materials: Epoxy putty adhesive becomes rigid once cured, making it unsuitable for applications that require flexibility.

- Unsuitable for High-Stress Applications: In high-stress situations, this may not provide the necessary flexibility and could fail.

Common Uses of Epoxy Putty Adhesive

Epoxy putty adhesive finds applications in various fields due to its versatility and strong bonding capabilities.

- Home Repairs and Maintenance: Whether fixing broken ceramics or patching up walls, this is a handy tool for household repairs.

- Automotive Repairs and Restorations: It is commonly used in automotive repairs, such as fixing dents, sealing leaks, and securing loose parts.

- Industrial Applications: Heavy machinery repairs, equipment bonding, and metal fabrications often rely on the strength of epoxy putty adhesive.

- Arts and Crafts Projects: It is popular among artists and crafters for creating sculptures, models, and other artistic creations.

Tips for Using Epoxy Adhesive Effectively

To get the best results, follow these essential tips:

- Surface Preparation: Clean and roughen the surfaces to be bonded for optimal adhesion.

- Mixing Ratios and Consistency: Accurately measure and mix the components in the correct ratio for effective curing.

- Applying Epoxy Putty Adhesive: Apply the adhesive evenly and smoothly to ensure a strong bond.

- Proper Curing Conditions: Follow the manufacturer’s instructions regarding temperature and curing time for the best results.

- Sanding and Finishing Techniques: Once the adhesive has cured, sand and finish the bonded surfaces for a seamless look.

Tricks for Overcoming Common Challenges

When using you may encounter some challenges. Here are some tricks to overcome them:

- Extending Working Time: Place the in the fridge before use to slow down the curing process.

- Removing Excess Cured Epoxy Putty: Use a chisel or scraper to carefully remove excess adhesive after it has cured.

- Dealing with Air Bubbles: Gently tap or knead the to remove air bubbles before application.

- Enhancing Adhesion on Difficult Surfaces: Use sandpaper or a primer to improve adhesion on challenging materials.

Safety Precautions and Handling

While epoxy putty adhesive is a powerful bonding agent, it is essential to use it safely. Follow these safety precautions:

- Proper Ventilation and Personal Protective Equipment (PPE): Ensure you work in a well-ventilated area and wear gloves and a mask when handling the adhesive.

- Storage and Disposal Guidelines: Store away from children and pets and follow local regulations for proper disposal.

Conclusion

The epoxy putty adhesive is undoubtedly a game-changer in the world of adhesives. Its exceptional bonding strength, versatility, and various types make it a go-to solution for countless projects and repairs. From household fixes to industrial applications, it provides reliable and durable results.

However, users should be aware of its limitations, such as short working times and potential health hazards during application. By following the tips and tricks provided, anyone can become proficient in using it effectively and safely.